Specific excipient requirements in continuous tablet manufacturing

Posted: 29 June 2018 | JRS Pharma | No comments yet

Although traditional processes like direct compression, roller compaction, or wet granulation are used within the continous lines, the requirement for ingredients may differ from traditional batch processing.

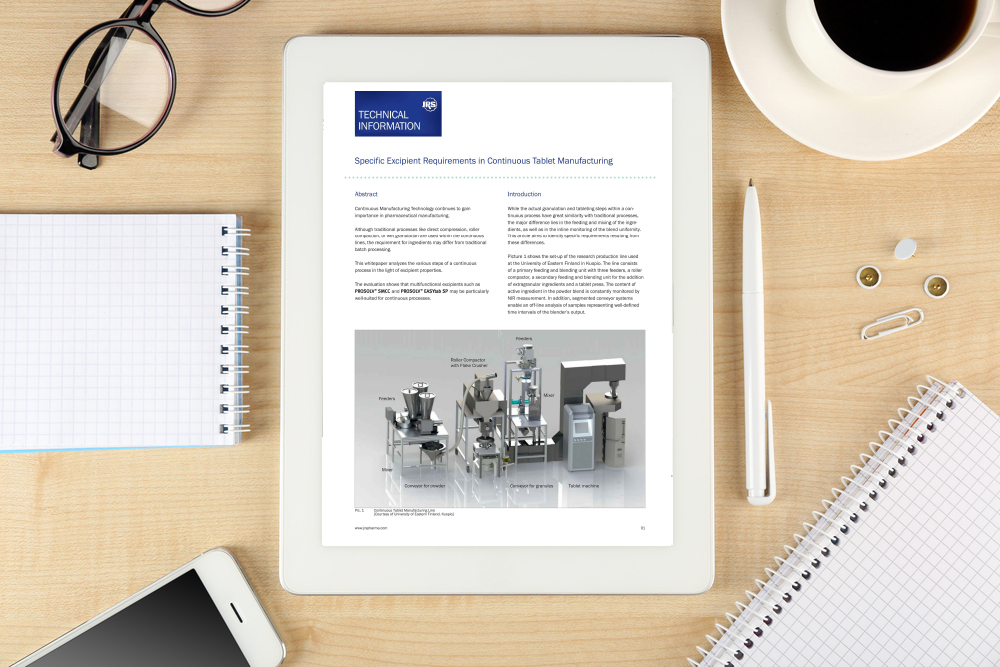

This whitepaper analyses the various steps of a continous process in the light of excipient properties.

This evaluation shows that multifunctional excipients such as PROSOLV® SMCC and PROSOLV® EASYtab SP may be particularly well-suited for continuous processes.

The rest of this whitepaper is restricted - login or subscribe free to access

Why subscribe? Join our growing community of thousands of industry professionals and gain access to:

- bi-monthly issues in print and/or digital format

- case studies, whitepapers, webinars and industry-leading content

- breaking news and features

- our extensive online archive of thousands of articles and years of past issues

- ...And it's all free!

Click here to Subscribe today Login here