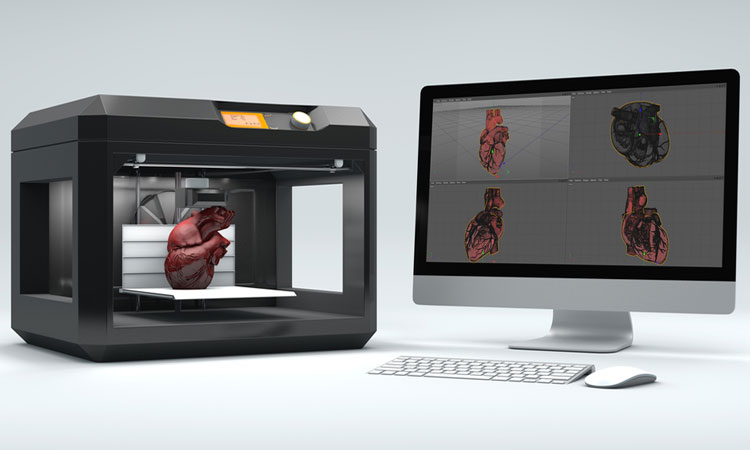

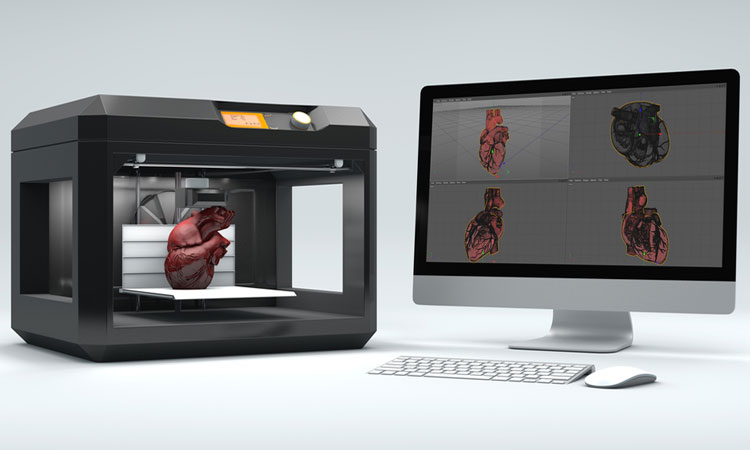

3D bioprinting technique for artificial organ tissue and arteries

Posted: 22 October 2018 | Iqra Farooq (European Pharmaceutical Review) | No comments yet

A 3D bioprinting technique could, in the future, allow the creation of human tissue structures for the analysis of various diseases…

Engineers at the University of Colorado Boulder have developed a 3D printing technique allowing for localised control of an objects firmness, opening new biomedical avenues that could include artificial arteries and organ tissues.

The study outlines a ‘layer-by-layer’ printing method featuring fine-grain, programmable control over rigidity, which allowed the researchers to mimic the complex geometry of blood vessels that are highly structured and yet must remain pliable. The researchers mentioned that these findings could lead to more personalised treatments for patients suffering from hypertension and other vascular diseases.

“The idea was to add independent mechanical properties to 3D structures that can mimic the body’s natural tissue,” said Dr Xiaobo Yin, Associate Professor in CU Boulder’s Department of Mechanical Engineering and the senior author of the study. “This technology allows us to create microstructures that can be customised for disease models.”

An engineered solution for viable artery and tissue replacement has proven difficult for hardened blood vessels, often associated with cardiovascular disease. The researchers found a unique way to take advantage of the role of oxygen in the final form of a 3D-printed structure.

“Oxygen is usually a bad thing in that it causes incomplete curing,” said Dr Yonghui Ding, a postdoctoral researcher in Mechanical Engineering and the lead author of the study. “Here, we utilise a layer that allows a fixed rate of oxygen permeation.”

By tightly controlling oxygen migration, and its subsequent light exposure, the researchers have the freedom to control areas of an object, making them harder or softer but keeping the overall geometry the same.

“This is a profound development and an encouraging first step toward our goal of creating structures that function like a healthy cell should function,” Dr Ding said.

The ‘table-top’ sized printer is able to work with biomaterials down to 10 microns, with the researchers being hopeful that future studies will improve the capabilities even more.

“The challenge is to create an even finer scale for the chemical reactions,” said Prof Yin. “But we see tremendous opportunity ahead for this technology and the potential for artificial tissue fabrication.”

The study was published in the journal Nature Communications.