Scientists develop a new tool for imprinting biochips

Posted: 9 March 2018 | European Pharmaceutical Review | No comments yet

A new technology could allow researchers to fit more biochemical probes onto a single biochip and reduce the cost of screening and analyzing changes associated with disease development…

3-D printing has gained popularity in recent years as a means for creating a variety of functional products, from tools to clothing and medical devices. Now, the concept of multi-dimensional printing has helped a team of researchers at the Advanced Science Research Center (ASRC) at the Graduate Center of the City University of New York develop a new, potentially more efficient and cost-effective method for preparing biochips (also known as microarrays), which are used to screen for and analyse biological changes associated with disease development, bioterrorism agents, and other areas of research that involve biological components.

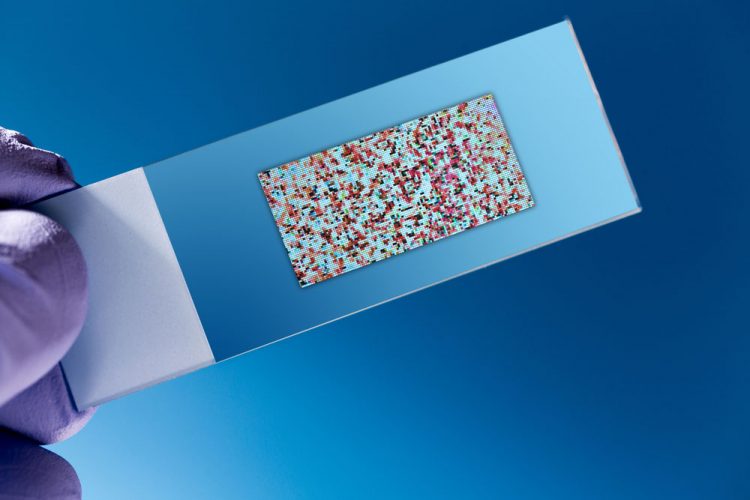

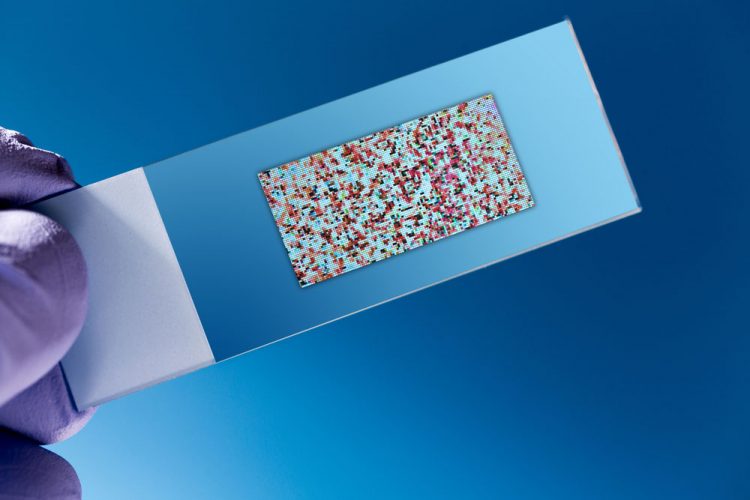

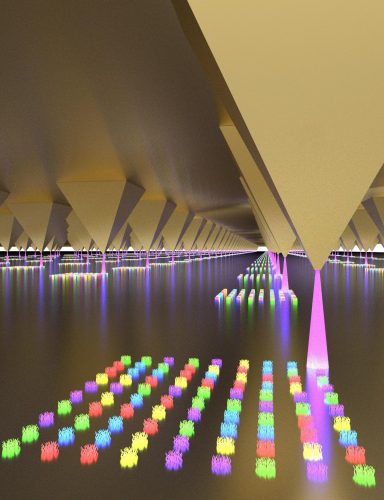

Biological probes are patterned into biochips using nanoscopic light-pens, allowing researchers to increase the number of probes that can be immobilised in a single chip. Advanced Science Research Center at the Graduate Center, CUNY

The researchers have combined microfluidic techniques with beam-pen lithography and photochemical surface reactions to devise a new biochip printing technique.

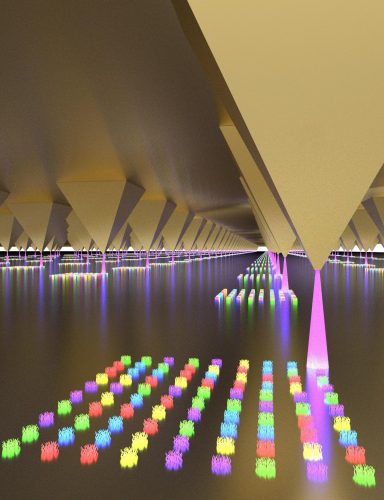

The method involves exposing a biochip’s surface to specific organic reagents and then using a tightly focused beam of light to adhere the immobilised reagents to the chip’s surface. The process allows scientists to repeatedly expose a single chip to the same or different factors and imprint the reactions onto different sections of the biochip. The result is a biochip that can accommodate more probes than is achievable with current commercial platforms.

“This is essentially a new nanoscale printer that allows us to imprint more complexity on the surface of biochip than any of the currently available commercial technologies,” said Adam Braunschweig, lead researcher and Associate Professor with the ASRC’s Nanoscience Initiative. “It will help us to gain a much better understanding of how cells and biological pathways work.”

An additional benefit of the new tool is that it allows researchers to reliably print on a variety of delicate materials–including glasses, metals, and lipids–on the length scale of biological interactions, and without the use of a clean room. It also allows scientists to fit more reactive probes onto a single chip.

These improvements could, in theory, reduce the cost of biochip-facilitated research.

ASRC scientists are now exploring ways to fine-tune their new technique for creating these biochips. “We want to be able to record even more complex surface interactions and reduce our resolution down to a single molecule,” said ASRC Research Associate Carlos Carbonell, the paper’s lead author. “This technique gives rise to a new method of microarray creation that should be useful to the entire field of biological ‘omics’ research.”

The paper has been published in the journal Chem.

Related topics

3D printing, Microarrays, Microbial Biological Manufacturing, QA/QC