Optimal biosafety cabinet cleaning strategy proposed

Posted: 24 March 2025 | Catherine Eckford (European Pharmaceutical Review) | No comments yet

The research highlights a potential approach to address cross-contamination challenges during cell-processing operations.

Innovative research suggests that a combination cleaning approach can “reliably” eliminate mycoplasma, viruses, and endotoxin contaminants in biosafety cabinets.

The study proposed that wiping with various disinfectants (distilled water, ethanol, and benzalkonium chloride (BKC)), together with UV irradiation was optimal for changeover cleaning.

Optimising contaminant removal in biosafety cabinets

Mizuno et al. stated that their study is the first “to provide reference data of different cleaning methods for mycoplasmas, viruses, and endotoxins in cell-product manufacturing facilities”, offering a unique approach to addressing cross-contamination cell-product manufacturing.

[The study] is the first to provide reference data of different cleaning methods for mycoplasmas, viruses, and endotoxins in cell-product manufacturing facilities”

The authors explained that these contaminants have yet to be analysed thoroughly, due to “the complexity of the analytical methods”.

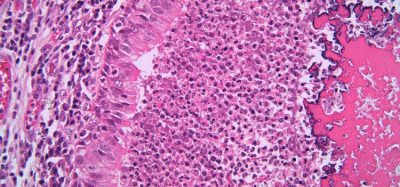

Their paper, published in Regenerative Therapy, described a risk-based approach to determine appropriate cleaning methods and lower the risk of cross-contamination in biosafety cabinets.

While past research has proposed different approaches to remove mycoplasma, viruses, and endotoxins, “an optimal method has not yet been determined”, Mizuno et al. prefaced. This is compounded by the efficacy of traditional removal methods remaining “unclear”.

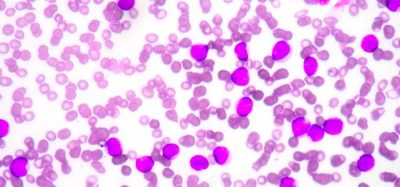

In their paper, the authors highlighted the importance of their study, citing that contaminants can “inadvertently persist in the manufacturing area”, since cell products need to be processed manually. For example, mycoplasmas and bacteria can be introduced into the site by operators or the environment, resulting in cross-contamination.

Efficacy of the combination cleaning method for mycoplasma

In evaluating the cleaning efficiency to eliminate mycoplasma, the researchers reported that the media “tended to be acidic”, suggesting that that “the UV- and BKC- treated specimens did not have mycoplasma growth”.

Other results were surprising, according to the team. “Mycoplasma was detected in all SUS304 plates cleaned with [ethanol]. Additionally, 66.7 percent of the plates from the [distilled water] group contained mycoplasma, showing no significant differences from the other groups”, the authors wrote.

Looking ahead, Mizuno et al. anticipated that their research could “support the development of evidence-based management strategies for ensuring safe cell-product processing”.