Sustainable method converting waste into pharmaceuticals developed

Posted: 3 March 2025 | European Pharmaceutical Review | No comments yet

The innovative artificial photosynthesis technique offers a new approach to eco-friendly chemical production.

A team of researchers in Japan have developed a novel artificial photosynthesis method that transforms waste organic compounds into valuable pharmaceuticals and energy using sunlight and water. The approach, known as artificial photosynthesis directed toward organic synthesis (APOS), represents a major step forward in sustainable chemical manufacturing.

A new approach to artificial photosynthesis

[The research] represents a major step forward in sustainable chemical manufacturing”

Artificial photosynthesis mimics the natural process by which plants use sunlight, water and carbon dioxide to produce glucose. However, with the innovative APOS technique, “waste products, which are often produced by other processes, were not formed; instead, only energy and useful chemicals were created,” Professor Susumu Saito at Nagoya University in Japan explained.

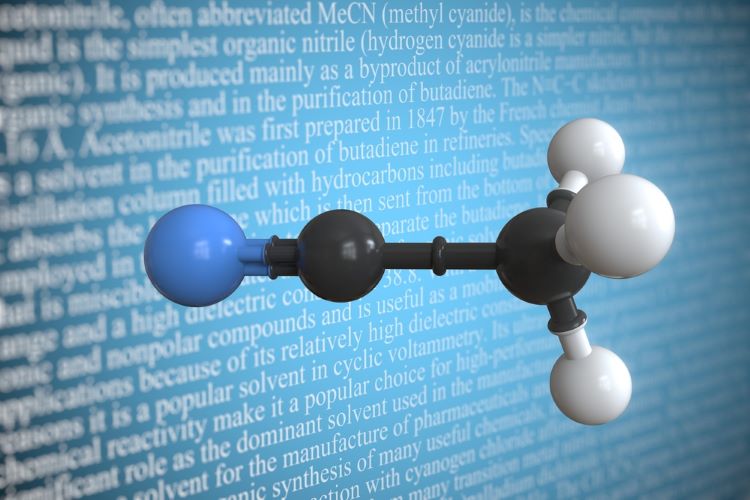

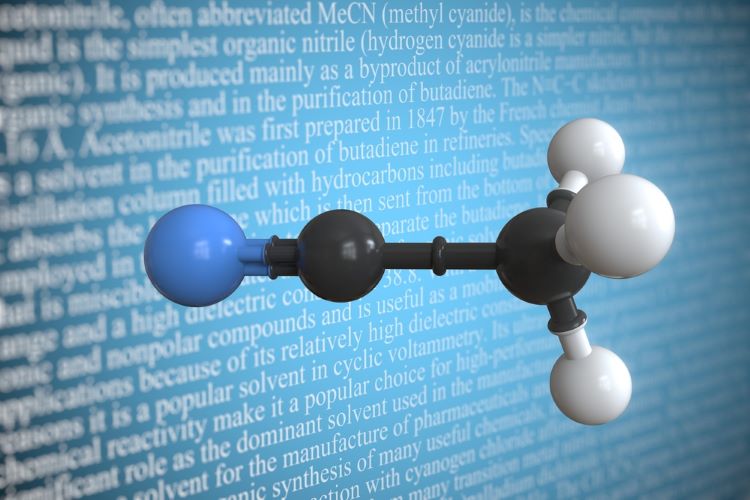

The novel process is driven by two inorganic semiconductor photocatalysts, which enable the decomposition of organic waste and water, facilitating the synthesis of useful organic compounds alongside the production of ‘green’ hydrogen.

The APOS technique also demonstrated its ability to modify existing pharmaceuticals”

In their chemical experiments, the researchers successfully synthesised more than 25 different alcohol and ether products from various organic raw materials. These included analogues of an antidepressant and a hay fever medication. The APOS technique also demonstrated its ability to modify existing pharmaceuticals, such as a drug used to treat high lipid levels.

Implications for sustainable chemical production

Professor Susumu Saito highlighted the sustainability benefits of the experimental method, particularly in reducing industrial waste. “Our state-of-the-art technique could potentially produce useful carbon materials without forming carbon dioxide and waste,” he said. The investigators specifically tested acetonitrile – a byproduct of polymer and carbon nanofibre production – as a raw material, successfully converting it into valuable chemical products.

The team anticipated that their research could pave the way for the sustainable production of medical and agricultural chemicals. The paper was published in Nature Communications.

Related topics

Industry Insight, Manufacturing, polymers, Processing, Production, Sustainability, Therapeutics