Achieving VLP continuous production with digital twins

Posted: 1 August 2024 | Catherine Eckford (European Pharmaceutical Review) | No comments yet

Utilising a digital twin for an advanced process control strategy facilitates additional productivity gains of 20 percent at 99.9 percent reliability, the authors shared.

A study has illustrated the development and validation steps for a digital twin “combining a physical-chemical-based mechanistic model for all unit operations with a process analytical technology (PAT) strategy” for bioprocessing.

According to Hengelbrock et al., developing and incorporating digital twins for Quality-by-Design (QbD)-based process approaches is a major challenge in modern biotechnology. For example, flexible operation and automation through advanced process control (APC) with PAT are key requirements.

The paper highlighted several benefits of digital twins for bioprocessing and biomanufacture, such as supporting accelerated process design and development. Furthermore, they enable different plants to be operated in parallel. As such, this “drastically” decreases operator workload, the authors wrote.

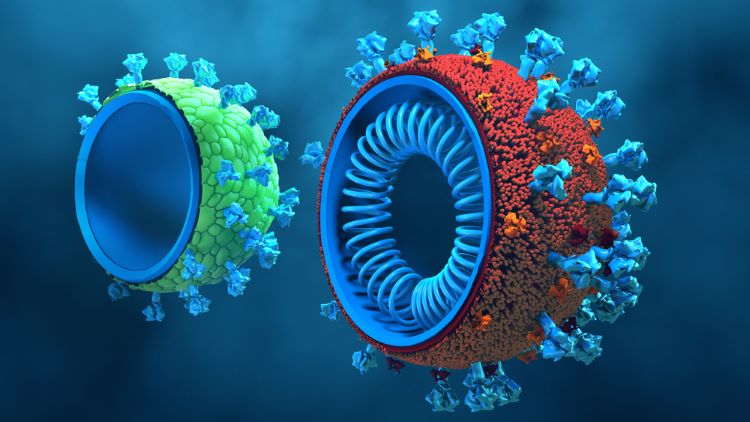

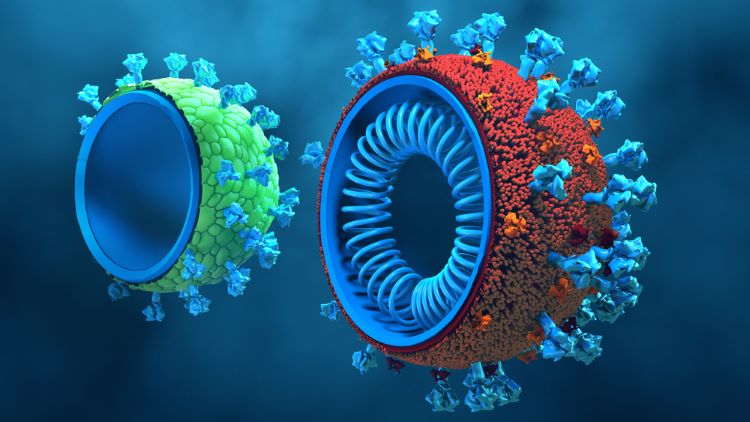

For drug substances specifically, they noted that virus-like particles (VLPs) have shown “considerable potential” as flexible vaccine platforms.

Cultivation for bioprocessing

In their study on bioprocessing and continuous bioproduction and digital twins, Hengelbrock et al. performed initial tests with “standard [alternating tangential flow filtration] equipment and membranes comparable to those used in studies with [Chinese hamster ovary] (CHO) cells producing monoclonal antibodies (mAbs)”. The paper noted that this was done based on insight from literature on the transition from fed batch to perfusion.

In the study, cultivation was performed “as a fed batch and then continued as perfusion in [alternating tangential flow filtration] mode”. The team reported that the filter was “completely blocked after three hours of perfusion”.

As a result, they stated that this enabled “150 mL of permeate to be collected, which corresponds to a filter capacity of approximately 50 L/m2”.

Comparing the performance of normal flow depth filters and perfusion in alternating tangential flow filtration mode “showed blocking behaviour due to cell debris and insufficient particle removal, which led to tangential flow filtration (TFF) being investigated for proof of increased filter capacity by higher tangential flow”, the research found.

Further results

The bioprocessing-focused paper continued: “As expected, during cultivation, the total number of particles in the medium increases over time. In addition, as the number of cells increases, more [extracellular vesicles] are released into the medium, and the proportion of the product in the total number of particles decreases.

“Furthermore, an increase in the mean diameter can be observed over time. This indicates that the proportion of larger vesicles and possibly aggregates of [extracellular vesicles] and product increases”.

The proposed downstream process contrasts with existing processes fully integrated, closed, and continuous”

An additional conclusion from the digital twins study found total process yield as “59 percent (factor 1.5–3 higher than literature) with 99 percent decrease of DNA (1.5 ng/doses) and protein, thereby ensuring regulatory demanded purity levels of less than 10 ngDNA/doses gaining product specification”.

Overall, the paper demonstrated the benefits of autonomous operation approaches for manufacturing scale. The proposed downstream process contrasts with existing processes fully integrated, closed, and continuous, the authors explained.

This paper on bioprocessing and digital twins was published in ACS Omega.

Related topics

Biologics, Biopharmaceuticals, Bioprocessing, Bioproduction, CHO cells, Data Analysis, Digital, DNA, Downstream, Drug Development, Drug Manufacturing, Industry Insight, Process Analytical Technologies (PAT), Processing, Proteins, QA/QC, Quality by Design (QbD), Research & Development (R&D), Sieving & Filtration, Technology, Therapeutics