Control strategy could facilitate faster bioburden detection

Posted: 21 March 2024 | Catherine Eckford (European Pharmaceutical Review) | No comments yet

According to the paper, the control strategy for rapid bioburden testing provides manufacturers with enhanced capabilities for process control.

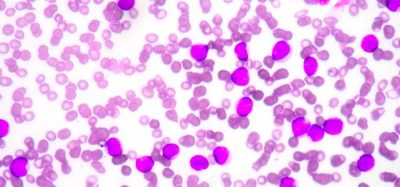

Biopharma and bioprocessing experts have proposed an approach that uses a two-tiered control strategy for rapid bioburden testing, that can beneficially, “leverage faster detection times”. It comprises of a “fast (but possibly less sensitive) test” for process monitoring which then initiates “action for a second, longer duration test which is used to confirm and quantify the presence of bioburden and identify the [ microbial ] organism.”

Specifically, the first assay is “suited for continuous in-process demonstration of the validated state”. The second however, is suitable for managing risk to the patient, according to the paper.

Application of rapid microbial testing

The control strategy uses short-duration rapid microbial testing as a monitoring tool “to trigger subsequent and only as needed confirmatory testing”. As such, the authors stated that it considers current capability limitations of rapid microbial testing as well as the risk-based considerations of meaningful sample points.

According to the authors, the approach could be used to establish process control alongside real time continuous processes.

In contrast, traditional approaches can be challenging on process analytics when utilising integrated continuous bioprocessing (ICB) enables for process intensification, the authors highlighted.

The paper explained that there is “often a trade-off with current [rapid microbial] technologies between test duration and accuracy.”

Traditional microbial methods provide minimal value to ICB processes because it takes longer data to become available compared to a typical full cycle of the manufacturing process, Ramos et al. elucidated.

Enhancing process control

The authors insisted that microbial detection methods should align with the needs of modern processes such as integrated continuous bioprocessing.

This is because “especially when coupled with ICB, the status quo is simply ineffective at providing appropriate and timely feedback on the state of microbial control of the process.”

While ICB “can accelerate manufacturing of biologics and has potential to increase productivity and reduce the cost of goods sold”, microbial control in an ICB process “is a challenge due to sampling and time to result limitations”, the authors stated.

“facilities of the future should look to microbial detection technologies that are fast, sufficiently accurate, able to integrate physically with the manufacturing process, and allow for streamlined automated data analysis”

Ramos et al. concluded that together with application of rapid microbial technology, “a strategic shift in the corresponding control strategy such as with the two-tiered approach [described in the paper offers] a comprehensive solution”. Chiefly, the researchers stated that it provides manufacturers with enhanced capabilities in addressing the requirements of their processes.

Considering the future, the authors asserted: “facilities of the future should look to microbial detection technologies that are fast, sufficiently accurate, able to integrate physically with the manufacturing process, and allow for streamlined automated data analysis.”

The paper was published in Biotechnology Progress.