Takeda to build £600m plasma therapy manufacturing site

Posted: 23 March 2023 | Catherine Eckford (European Pharmaceutical Review) | No comments yet

Takeda’s largest manufacturing capacity expansion investment in Japan will fund the build of a new facility for plasma-derived therapies.

Through its investment of approximately £600 million, Takeda plans to build a new manufacturing facility for plasma-derived therapies (PDTs) in Osaka, Japan. This is Takeda’s largest ever investment in manufacturing capacity expansion and will be the largest facility of its kind in Japan.

This is Takeda’s largest ever investment in manufacturing capacity expansion and will be the largest facility of its kind in Japan.”

“The new facility will provide a plasma fractionation capacity of more than two million litres per year,” commented Thomas Wozniewski, Global Manufacturing and Supply Officer at Takeda.

The Osaka site increases the capacity of Takeda’s current plasma manufacturing site in Narita, Japan almost five-fold. Additionally, it will add incremental capacity to its global manufacturing network.

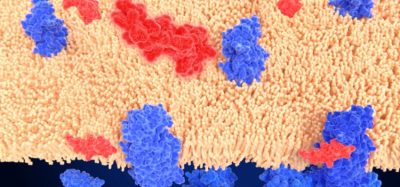

Manufacturing plasma-derived therapy

The facility will be built to the highest global manufacturing standards, including the latest automation and advanced digital technologies. The fully integrated plant will comprise of teardown, fractionation, purification, filling, finishing capabilities as well as a cold storage warehouse.

Design of the plant will be environmentally friendly to support Takeda’s goal of achieving net-zero greenhouse gas emissions related to operations including scopes 1 and 2 before 2035.

The demand for plasma-derived therapy has grown significantly over the last 20 years as diagnoses of rare diseases and earlier treatment of complex chronic diseases have improved. While the therapies address areas of high unmet medical need and there is growing demand in Japan, treatment with immunoglobulin (IG) is currently much lower than in other parts of the world.

Wozniewski added that the facility “will deliver high quality products to patients reliant on PDTs, including those with diseases for which there are no alternative treatments.”

Takeda has made continuous investment in innovative medicines such as Leuplin®, an Luteinizing hormone-releasing hormone (LH-RH) agonist; Alofisel®, a cell therapy line that requires highly advanced manufacturing technology.

Takeda’s existing Narita plasma manufacturing site will continue day-to-day operations until at least the end of the decade.

The new state-of-the-art facility is expected to be operational by around 2030.

Related topics

Big Pharma, Biopharmaceuticals, business news, Drug Development, Drug Manufacturing, Drug Supply Chain, Industry Insight, investment, Manufacturing, Research & Development (R&D), Sustainability, Technology, Therapeutics