Identifying origin of fungi in cleanrooms

Posted: 22 March 2023 | Catherine Eckford (European Pharmaceutical Review), Tim Sandle (Bio Products Laboratory) | 1 comment

Microbiology expert Tim Sandle’s recent video examined identifying the origin of fungi in pharmaceutical cleanrooms.

In a recent video, pharmaceutical microbiology expert Tim Sandle highlighted areas of concern and attention relating to mycological contamination control in manufacturing.

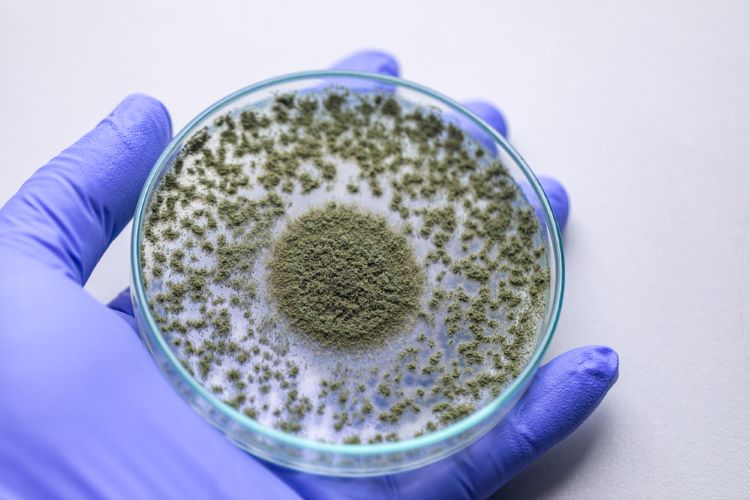

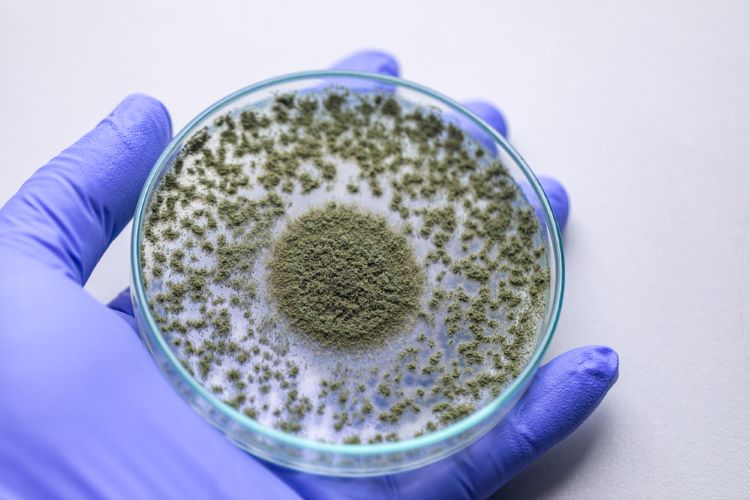

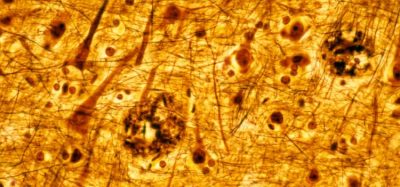

Pharmaceutical product recalls due to fungal contamination have been increasing. These, together with environmental monitoring trend data, highlight several fungal contamination issues associated with pharmaceutical cleanrooms, cold rooms and other controlled areas. Species of filamentous mould include: Cladosporium, Penicillium, Aspergillus, Alternaria, Fusarium, and Paecilomyces).

There are particular areas in cleanroom environments where control breakdown can increase the likelihood of fungi being found, Sandle noted. He stated that understanding the likely point of origin is essential for rectifying and preventing recurrence.

Sources of fungi contamination

In the video, Sandle identified several sources of fungi contamination. These include door kick plates, bags, incubators, boxes, markers, intervention equipment, trolley cartwheels, ceiling tiles, poorly maintained flooring and in some cases, high-pressure impingement application devices for applying germicides.

Air handling systems are especially vulnerable, Sandle observed. Studies have shown a high population of fungi are associated with the early stage of heating, ventilation and air conditioning (HVAC) systems. So damage to a high-efficiency particulate absorbing (HEPA) filter or a weakness with a terminal HEPA filter seal provide ready conduits for fungal entry into the cleanroom.

Once inside the cleanroom, the possibility of fungal survival arises due to increases in ambient temperatures and under conditions of higher humidity. Wet or damp areas are a further factor which can encourage fungal growth in cleanrooms. Dispersal of fungal spores is influenced by disturbance forces, a further reference to vibrational waves, as well as air distribution.

Structural issues as potential sources

Other factors of concern include deficient room pressurisation, vibrations from construction, poor engineering designs related to sprinkler systems, wall or floor damage, and light fixtures. These latter issues are particularly acute for aging, legacy facilities. According to Sandle, a key example is the site where all damage and materials like plasterboard are exposed or in relation to painted surfaces. This is because many species of fungi are adept at utilising paint as a growth substrate.

Another variable relates to facility design and maintenance (including environmental control systems relating to HVAC). Where works are undertaken that expose the cleanroom to the external or to an unclassified environment, this raises the risk of fungal spore entry and with this the challenges of elimination or removal.

it is imperative to consider all factors that can contribute to mould issues, as part of an effective contamination control strategy (CSS), as signalled in the revision to Annex 1.”

As well as weaknesses with cleanroom design, observing process flows is also of importance. Issues with fungal ingress are associated with items brought into cleanrooms, especially where effective transfer disinfection is not observed. The introduction of unsuitable items is also of concern, such as cardboard, a material that is notoriously difficult to clean and which has no place in the cleanroom.

As the potential sources of fungi contamination are so varied, it is imperative to consider all factors that can contribute to mould issues, as part of an effective contamination control strategy (CSS), as signalled in the revision to Annex 1.

Sandle confirmed that generally, the detection of fungi within the cleanroom signals as wider and often more serious control breakdown than with the presence of bacteria.

Remedial “action will only be effective where the root cause has been determined,” Sandle concluded.

Thanks Tim Sandle. I recently found fungal in Class ISO 7 (filling Room) can you please share what measure must be taken to eliminate fungus?