Partnership to stabilise essential medicines supply with synthetic biology

Posted: 16 August 2021 | Hannah Balfour (European Pharmaceutical Review) | No comments yet

Under a new collaboration, Antheia will use Ginkgo Bioworks’ cell programming platform to expand the capabilities of its whole-cell engineered pharmaceutical production pathways.

Antheia and Ginkgo Bioworks have announced that they will collaborate to accelerate the development and production of essential plant-based medicines.

Under the collaboration, Antheia will leverage Ginkgo’s high throughput enzyme design and screening capabilities to broaden its pipeline of critical active pharmaceutical ingredients (APIs) and key starting materials (KSMs).

In the announcement the companies explained that almost half of all medicines are sourced from nature, with many of the most widely used essential medicines obtained directly from medicinal plants. The World Health Organization (WHO) classifies “essential medicines” as medicines “that satisfy the priority health care needs of the population.” However, the supply chains for most critical plant-based medicines are fragile, said the companies, and depend on a years-long process of growing, harvesting, transporting and processing specialty plants. Therefore, when challenged by extreme demand or constrained supply, such as during the COVID-19 pandemic, many plant-based medicines – including widely used analgesics and sedatives – can be in shortage.

“Antheia is committed to using synthetic biology to enable more equitable access to essential medicines,” explained Kristy Hawkins, Chief Scientific Officer and co-founder of Antheia. “By partnering with Ginkgo Bioworks, a global leader in organism engineering, we are greatly increasing our ability to develop essential medicines at the speed and scale necessary to drive change in global pharma supply chains.”

The enterprises stated that synthetic biology platforms, such as theirs, make it possible for critical medicines to be produced on-demand in a much more efficient and environmentally friendly process. Additionally, when it comes to plant-based pharmaceuticals, biomanufacturing has significant advantages in supply chain resiliency and agility, cost, quality control, sustainability and efficiency compared to the conventional production methods, which are based on crop farming.

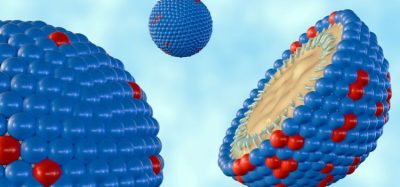

Antheia is focused on plant-inspired pharmaceuticals that are too complex to be produced through scalable synthetic chemistry processes. It has managed to efficiently produce these highly complex pharmaceuticals by pioneering whole-cell engineering, a technique that reconstructs multi-step biosynthetic pathways in yeast cells. As the company brings its engineered microbes to commercial scale, it continues to optimise the strains to ensure highly efficient production of the pharmaceutical compound of interest. Through this partnership, Antheia plans to leverage Ginkgo’s cell programming platform and biological codebase to expand and accelerate its strain and enzyme engineering work.

“Antheia is at the cutting edge of synthetic biology innovation, and its whole-cell engineering platform is capable of producing entire classes of medicines that were previously inaccessible,” said Barry Canton, co-founder and Chief Technology Officer at Ginkgo Bioworks. “We are thrilled that Ginkgo’s platform can support innovators like Antheia as they create next generation manufacturing technologies for essential medicines.”

Related topics

Active Pharmaceutical Ingredient (API), Bioproduction, Drug Manufacturing, Drug Supply Chain, Sustainability, Technology, Therapeutics