Could precipitation reduce the cost of antibody production?

Posted: 16 April 2021 | Hannah Balfour (European Pharmaceutical Review) | No comments yet

Using a new precipitation method eliminates the need for the costly chromatography process and could make antibody therapies more affordable to produce, according to Andrew Zydney.

A researcher has identified a new method to manufacture antibodies, which could drive down the production cost and make antibody therapies more accessible to a broader range of patients.

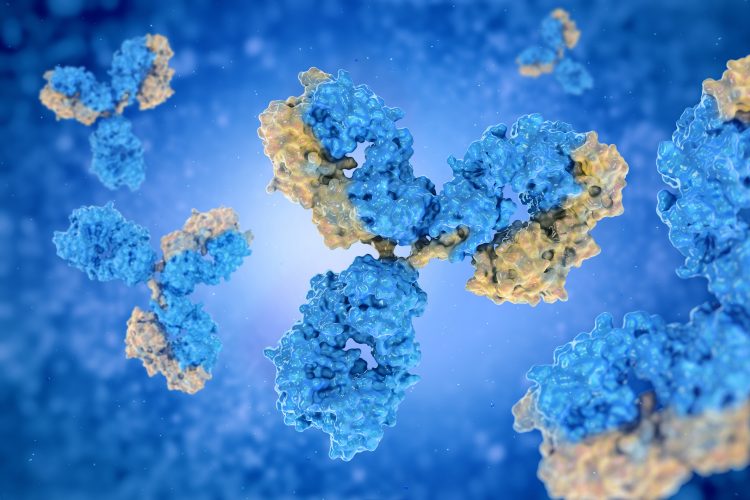

Andrew Zydney, Bayard D. Kunkle Chair and professor of chemical engineering at Pennsylvania State University (Penn State), US, who discovered the method stated: “If you look at the top 10 best-selling medications, by annual sales, eight are in the category of monoclonal antibodies. Additionally, every year, individuals and insurance companies spend upwards of $100 billion on antibodies, with costs to treat a single patient often exceeding $50,000. There remains a huge unmet need for these products in treating a growing range of diseases.”

Such treatment include antibody injections for those with chronic diseases such as cancer, psoriasis, Crohn’s disease and arthritis, as well as their more recent use as a promising treatment for severe cases of COVID-19.

Zydney’s new protein purification process, known as precipitation, involves adding zinc chloride and polyethylene glycol, a water-soluble polymer, to a solution containing the antibody. This causes the antibody to precipitate so that the impurities can be washed away.

Though the precipitation process has been used for 70 years in blood plasma processing, it has never been used for the commercial production of antibodies, according to Zydney. He explained that, since zinc chloride is a simple salt, his process is much cheaper than other purification methods. It also saves time, said Zydney, as it can yield large quantities of proteins in short periods of time.

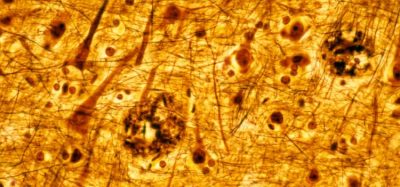

Currently, antibodies are produced using a process called Protein A affinity chromatography, where the antibody binds to Protein A, which is immobilised in a chromatography column. The impurities can be washed away from the bound antibody, after which the pH level is adjusted to recover the purified antibody product. A single Protein A chromatography column can cost more than $10 million.

“That is just one step in the current manufacturing process, and it is what makes antibody manufacturing so expensive,” Zydney explained. He continued that using precipitation eliminates the need for the chromatography process, as antibodies are purified directly from the solution by filtration through hollow fibre membranes.

He concluded: “What we do in our research group is relatively small scale. But the precipitation process has the potential to be easily scaled up, potentially enabling biopharmaceutical companies to produce lower-cost antibodies for the patients who need them.”

The research results were published in Biotechnology Progress.