Expert View: What ADC evolution means for manufacturing

Posted: 19 December 2018 | Jyothi Swamy, Lisa McDermott | No comments yet

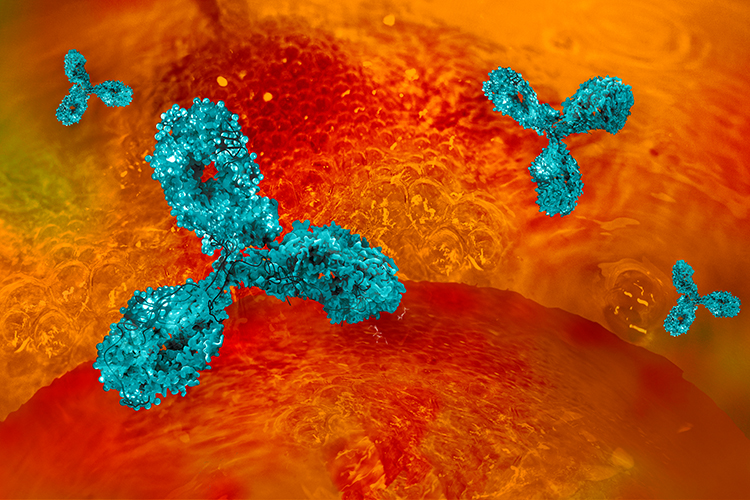

The evolution of antibody-drug conjugates (ADCs) is a spectacular example of how global research can sculpt a new technology. Years of molecular and cell biology, conjugation chemistry and immunology progress has enabled a cytotoxic agent paired with a tumour-specifi c antibody to become mainstream cancer therapy.1 Today, advances continue, explains Jyothi Swamy, Head of Global Marketing at Merck KGaA and Lisa McDermott, Senior Manager in Process and Analytical Development at Merck KGaA.

CONJUGATION, linker and toxin chemistries have progressed, as have manufacturing and quality control. Because of their complexity, 80 percent of ADC projects are now outsourced to contract development and manufacturing organisations (CDMOs).2 In fact, on average, five to 10 CDMOs, which may be globally dispersed, make up the supply chain. What do these changes mean for CDMOs adapting to meet ADC customer demands?

Evolving ADCs demand sophisticated manufacturing

Ten years ago, ADC manufacturing was small-scale. Heterogeneous ADCs with variable drug-to-antibody ratios (DARs) were linked via monovalent, non-cleavable bonds or by unreliably stable, acid-labile linkers to DNA-disrupting payloads. Much has changed since then. Today’s ADCs tend to be developed by site-specific conjugation technologies to achieve highly homogeneous DARs. Designers strive for multiple modes of action: bispecific monoclonal antibodies (mAbs) may contain multiple, dissimilar binding sites and deliver, for example, a toxin and activate natural killer cells. The conjugation processes and analytics for these agents are non-trivial. Antigen-binding fragments (Fabs) are another new development requiring extra manufacturing steps. Newer payloads – potent cytotoxins such as PBDs and tubulysins – necessitate special facilities and handling. Newer linkers incorporate products like Mersana’s Fleximer® platform, a polyvalent, biodegradable molecule for carrying multiple payloads. Additionally, hydrophilic linker modulation such as pegylation can mask a larger molecule from the immune system and decrease renal clearance to increase circulatory longevity. Ensuring stability and consistent pharmacokinetic (PK) and toxicity behaviour for all these products requires advanced analytical tools. Automated surface plasmon resonance (SPR) immunoassays, capillary electrophoresis (CE) and liquid chromatography-mass spectrometry (LC-MS), coupled with expertise in structure-activity relationship (SAR) drug design are now essential.

Conquer complexity with an experienced CDMO equipped to excel in this fast-changing industry

Merck has invested in facilities and processes to handle challenging supply chains and ensure efficiency, quality and security for our customers. To us, single-use systems with extractables and leachables documentation, process and analytical technology (PAT), testing and chromatography for purifi cation are indispensable. We offer advanced chemical unit operations, dedicated facilities www.merckmillipore.com/adc for high-potency biologicals and stateof- the-art analytical and quality control methodologies. Our experts enable customers to advance their development programmes rapidly through a platform approach and offer filing strategy support for late-stage studies. Whether it be understanding the structure-activity relationship around the antibody, linker and drug, or managing a complex supply chain, an experienced CDMO should have the skills and tools to help ADC developers navigate the challenges.

Issue

Related topics

Liquid Chromatography - Mass Spectrometry (LC-MS), Process Analytical Technologies (PAT), QA/QC, Research & Development (R&D), Single Use, Supply Chain, Technology