How automation and digital technologies will unlock the full potential of advanced therapies

Posted: 30 December 2024 | Dr Stephen Ward (CGT Catapult) | No comments yet

Automation and digital technologies, combined with workforce training and regulatory advancements, hold the key to transforming the production of advanced therapies. Dr Stephen Ward, Executive Director at CGT Catapult, shares how leveraging these innovations can facilitate the delivery of life-changing therapies to patients at scale, opening new possibilities for treating genetic and cellular diseases.

The use of advanced therapies – using cells or genes to achieve significant leaps in medical treatment – was perceived as a niche sector just a decade ago, but it has now started to garner a greater level of understanding and recognition in the pharmaceutical industry. Numerous groundbreaking advances have shown these therapies hold potential to revolutionise how we treat, and potentially cure, many conditions, including for patients with underlying genetic or cellular causes of disease that have been difficult to treat with conventional approaches.

It is estimated that only 4,000 doses of chimeric antigen receptor T cell (CAR-T) were manufactured in 2021, despite an eligible patient population of 450,000.1

It is estimated that only 4,000 doses of chimeric antigen receptor T cell (CAR-T) were manufactured in 2021, despite an eligible patient population of 450,000.1 In the US alone, one estimate suggests that the number of patients treated with gene therapy each year will grow to 60,000 by 2034.2 As the development and approval of cell and gene therapies shifts from rare to more prevalent conditions, the potential patient population will continue to grow and the gap between patient demand and the ability to supply will widen. The science that underpins the scaling up of advanced therapy manufacturing needs to keep pace to ensure that patients will have access to the therapies they need.

To satisfy this demand, the industry needs a concerted effort to build the physical and digital infrastructure to not only enhance but transform the current manufacturing capabilities of the sector.

Scaling production

Digital and automation technologies hold the key to unlocking this growth and meeting the challenge of scaling up manufacturing”

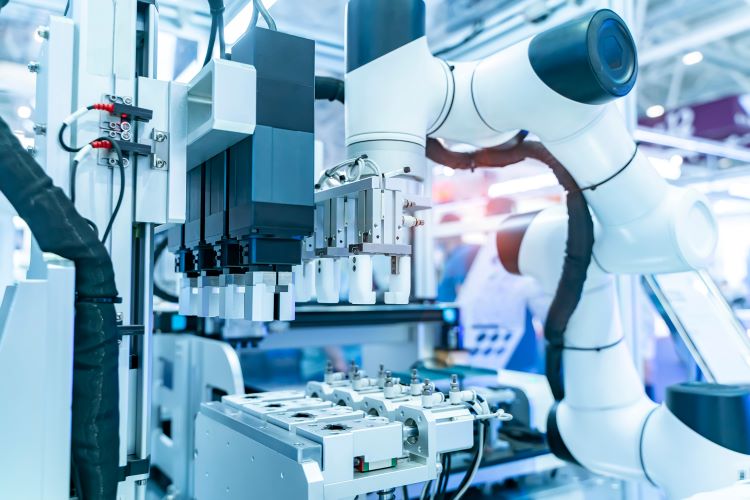

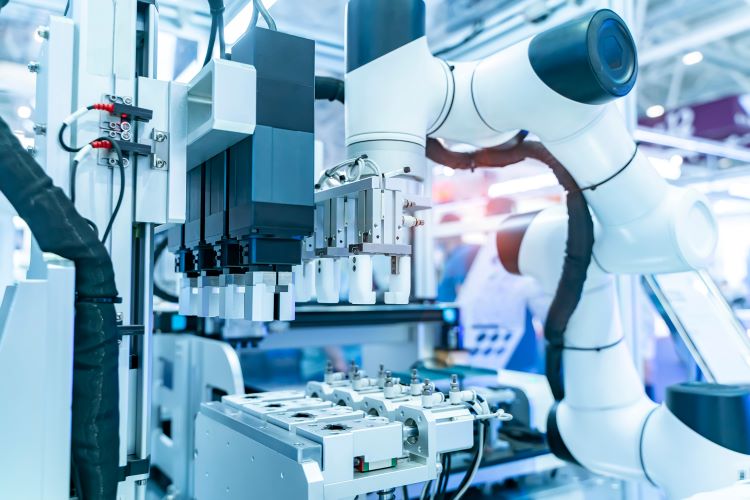

Digital and automation technologies hold the key to unlocking this growth and meeting the challenge of scaling up manufacturing.

There are two core models through which manufacturing systems can be automated. The first model involves the automation of an individual processing step. Adopting individually automated systems supports a closed end-to-end automated process for advanced therapy production, but often requires manual intervention to transfer material between different unit operations. Currently, there is limited interaction between individually automated systems.

In the second model, multiple unit operations are combined into a single platform. Although it is less flexible, this can reduce operator intervention and increase process consistency and efficiency. We are seeing various companies across the sector work on both models, with automated platforms coming to market that offer great promise.

One area of advanced therapy manufacturing to which these automation models can be applied is enhancing high-throughput approaches. For example, automation can enable safe manufacturing stream parallelisation, supporting a shift from scheduled to adaptive processing. Process analytical technologies (PATs) can be used here to monitor and control manufacturing processes in real time, improving product quality and increasing efficiencies.

There is also an important role for digital twins, virtual real-time counterparts of a physical object or process. The advanced therapy manufacturing sector is developing and applying these to better predict how cells will react to varying conditions throughout integrated automated manufacturing processes.

At the Cell and Gene Therapy (CGT) Catapult, we have set up digital and automation testbeds to allow academics and small to large companies to readily access and trial automation technologies in a pre-good manufacturing practice (GMP) environment. This gives companies the opportunity to assess the suitability of automated and digital platforms and technologies against their needs without having to commit to costly up-front investments. It creates critical mass around knowledge pools and opens up the potential to use data in a federated way.

Training the automation workforce

However, the full benefits of these technologies can only be realised if there is a workforce with the specialist skills needed to produce, operate and maintain digital and automation tools. A 2023 report by the Alliance for Regenerative Medicine identified skills gaps in analytical development and testing, quality control, and manufacturing of cell and gene therapies3 – a gap which is expected to widen in the coming years. In parallel, 15 percent of all respondents in the CGT Catapult’s UK 2023 skills survey felt an increase in digital and automation skills would be required in the next five years.4 There is a real need to attract cross-disciplinary talent to fill the gaps in robotics, automation, digital connectivity and data modelling that are beginning to form in the sector as it progresses towards digitalisation.

By creating more training pathways for the current and future workforce, the medicines manufacturing sector will be able to build robust talent pipelines to ensure the industry achieves its potential”

To get ahead of these emerging skills shortages, CGT Catapult is raising awareness of careers in cell therapy manufacturing. At the same time, we are working towards lowering the barrier to entering these careers through the skills programmes that we have developed with our partners and collaborators. Together, we have identified a need to enhance skills within automation, digital, quality and manufacturing. As a result, we are now looking to include digital and automation opportunities for apprentices through our Advanced Therapies Apprenticeship Community (ATAC).

By creating more training pathways for the current and future workforce, the medicines manufacturing sector will be able to build robust talent pipelines to ensure the industry achieves its potential.

Regulation

The widespread adoption of automated platforms at the large industrial scales needed to manufacture products for hundreds of thousands of patients may not be realised for another four to five years”

As well as specialised infrastructure and skills, the industry needs appropriate regulatory frameworks to ensure that these new manufacturing technologies can be safely and effectively implemented. This work has already started; for example, the US is running the Centres of Excellence in Regulatory Science and Innovation (CERSI) programme.5 In the UK, the Medicines and Healthcare products Regulatory Agency (MHRA) launched an initiative in December 2023 to establish new Regulatory Science and Innovation Networks (RSINs) to deliver agile and robust regulatory pathways and guidance to support health innovations.6

Testbeds like CGT Catapult are an important step in this process, allowing regulators to examine technologies ahead of their more widespread use, while also engaging with key industry players to understand their benefits and potential.

Seizing automation

In the next 12-18 months, it is likely that we will see regular implementation of individual system automation for distinct parts of the manufacturing process. Some companies are already developing closed and end-to-end automated systems, but as it stands these systems are only applicable to certain advanced therapies in development. The widespread adoption of automated platforms at the large industrial scales needed to manufacture products for hundreds of thousands of patients may not be realised for another four to five years. Within this timeframe we can expect to see completely integrated automated systems, high-density production systems, fully digitalised workflows and the adoption of robotic systems in routine manufacturing. It is therefore essential to understand how to design and deploy factories that can accommodate these technological innovations.

Given the short timeframe, the sector stands on the brink of a significant transformation. By seizing this opportunity to train the automation workforce and push for regulatory changes, the safe and effective scaling of manufacturing becomes achievable. This is essential to make life-changing advanced therapies accessible to the many patients who need them.

About the author

References

1. Tomtishen J. The Role of Automation in Meeting the Growing Demand for CAR T-Cell Therapies. American Journal of Managed Care [Internet]. 2023; 29:SP427–8. Available from: https://www.ajmc.com/view/the-role-of-automation-in-meeting-the-growing-demand-for-car-t-cell-therapies

2. Wong CH, Li D, Wang N, et al. The Estimated Annual Financial Impact of Gene Therapy in the United States. Gene Ther. 2023; 30 761–773.

3. Workforce Report: Gap Analysis for the Cell and Gene Therapy Sector. [Internet] Alliance for Regenerative Medicine. 2023. [cited 2024Aug]. Available from: https://alliancerm.org/sector-report/workforce/

4. UK Cell and Gene Therapy Skills Demand Report 2023. [Internet] Cell and Gene Therapy Catapult. 2023. [cited 2024Aug]. Available from: https://ct.catapult.org.uk/resources/skills-survey

5. Centers of Excellence in Regulatory Science and Innovation (CERSIs). [Internet] US Food and Drug Administration. 2022. [cited 2024Aug]. Available from: https://www.fda.gov/science-research/advancing-regulatory-science/centers-excellence-regulatory-science-and-innovation-cersis

6. MHRA Supports Launch Of Innovate UK’s First-Of-Its-Kind Initiative To Fund New Regulatory Science And Innovation Networks. [Internet] Medicines and Healthcare Products Regulatory Agency. 2023. [cited 2024Aug]. Available from: https://www.gov.uk/government/news/mhra-supports-launch-of-innovate-uks-first-of-its-kind-initiative-to-fund-new-regulatory-science-and-innovation-networks

Issue

Related topics

Big Pharma, Biopharmaceuticals, Drug Development, Regulation & Legislation, Research & Development (R&D), Technology, Therapeutics