International regulation: the importance of quality assurance in drug development

Posted: 4 July 2023 | Raquera Brown (Zymeworks) | 1 comment

Raquera Brown, Executive Director of Quality at Zymeworks offers quality and compliance professionals advice on how to navigate the often-complex regulatory space during development of innovative drugs like antibody therapeutics.

As drug development professionals know, global health crises like the COVID-19 pandemic provide the public with valuable insights into how clinical research and regulatory processes work. However, critical disciplines within the field responsible for ensuring safe and effective drug products, including quality assurance and compliance, remain mysterious or invisible to many. QA and compliance professionals face a variety of challenges during the development process for novel biologic drugs e.g. antibody therapeutics intended for clinical trials.

What are Antibody Drug Conjugates and Multispecific Antibody Therapeutics?

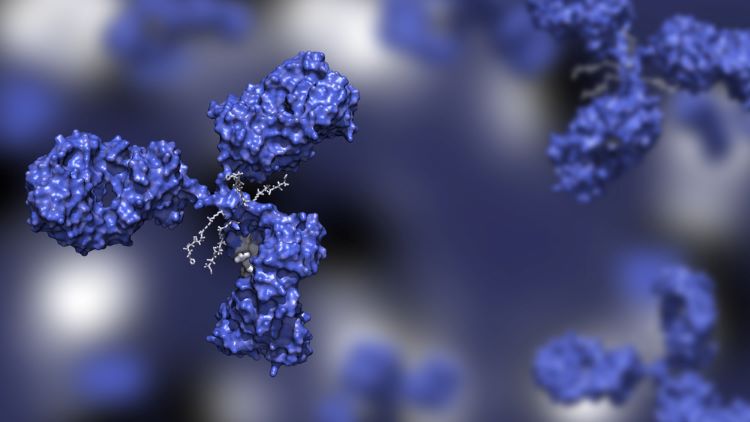

Antibody drug conjugates (ADCs) and multispecific antibody therapeutics are both innovative and relatively new classes of treatments being designed as targeted therapies for numerous difficult-to-treat diseases, including various cancers.

ADCs are complex therapeutics that leverage a monoclonal antibody’s ability to target specific cells combined with powerful cytotoxic drugs to deliver small molecule therapies directly to tumours. Since the first ADC was approved by the EMA in 2012, they have generated a great deal of interest in the oncology field because of their potential to address many of the challenges of traditional chemotherapy options. An ADC’s ability to specifically target specific cancer antigens without damaging healthy cells has resulted in improved drug tolerability and decreased systemic exposure to cytotoxins. This allows for increased payloads and therefore, increased therapeutic efficacy.

Multispecific antibody therapeutics (MsAbs) have also gained attention over the past three decades. They have been and are continuing to be developed to address various cancers by aiming for multiple targets expressed by tumour cells or cell populations or by enabling a patient’s T-cells to eliminate tumour cells. As is the case with ADCs, the ability of multispecific antibody therapeutics to directly target and eliminate cancer cells while minimising the risk of adverse effects has made them intriguing for drug developers.

QA and compliance considerations during the drug development process

While ADCs and multispecific antibody therapeutics have been researched for some time, their relatively recent introduction to the clinical trial and drug approval processes have meant that quality and compliance professionals must carefully consider several factors throughout the product development lifecycle. These include:

- Quality of starting materials

- Upstream manufacturing (thaw, expansion, harvest)

- Downstream processing (purification, filtration, sterilisation, filling)

- Contamination prevention

- Scalability

- Aseptic sampling practices

- Potency

- Purity

- Safety

- Data integrity

- Evolving regulatory authority expectations.

Drug development teams must overall demonstrate increasing process and product knowledge prior to the submission of an IND (Investigational Drug Application or equivalent) to a regulatory authority by taking the following factors into account:

- Consistency of materials

- Defined manufacturing process controls

- Comparability of products manufactured in different facilities

- Equipment qualification

- Aseptic filling processes

- Environmental monitoring

- Compatibility with administration systems

- Drug product characterisation, release and stability testing

those working in quality assurance and compliance must ensure that partners who are contracted to perform services demonstrate sufficiency… to meet standards held by regulatory authorities”

As drug development progresses from the bench scale R&D space to scale up to compliant manufacturing of product intended to be administered in Phase I to III clinical trials and commercialised, good manufacturing practice (GMP) requirements become increasingly stringent to ensure patient safety and more batches must be manufactured to scale. There are also numerous industry guidance documents for products manufactured for use in clinical trials and guidelines, some which are specific to advanced therapeutic drug products that must be consulted. Complex manufacturing processes and development of appropriately qualified or validated test methods present unique challenges which teams must overcome.

When outsourcing product manufacturing and testing, those working in quality assurance and compliance must ensure that partners who are contracted to perform services demonstrate sufficiency in several areas to meet standards held by regulatory authorities. These should include:

- Qualified personnel

- Facility design

- Quality management systems

- Contamination controls

- Data management systems

- Vendor management programmes

- Approved product specifications

- Equipment including laboratory apparatus.

Ensuring GMP compliance of contract manufacturers and laboratories requires negotiation of detailed quality agreements outlining specific responsibilities for contract givers and acceptors, perform routine quality audits, verify positive regulatory history and current regulatory licensure as key aspects of the vendor oversight programme.

Quality assurance and compliance-related plans are affected by supply chain issues. Materials can be costly for drug product manufacturers and may not be readily available from the preferred qualified source with long lead times. While quality and compliance teams are not primarily focused on the cost, pricing impacts every aspect of the work, from materials used in testing to manufacturing supplies.

The key objectives of any quality and compliance team in the drug development space is to ensure establishment of effective risk management strategies to identify and mitigate manufacturing related risks. Quality and compliance professionals need to stay abreast of and interpret the latest regulatory authority requirements, expectations set by governing agencies and guidelines set forth by The International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH). This will help to stay ahead of any changes that may impact a therapeutic’s chances or timeline for approval. Quality and compliance professionals also define bioanalytical assays such as potency assays, critical quality attributes (CQAs) and quality target product profiles (QTTPs).

What are the main challenges quality assurance and compliance professionals face during the drug development and review process? How can they be addressed?

In the case of novel advanced therapeutics, standards frequently change as new information about the drug product classes become available and regulatory authorities implement or update guidelines to ensure that they are both safe and effective for patients. Regulatory professionals must establish appropriate communication with representatives at regulatory agencies including the US Food and Drug Administration (FDA), European Medicines Agency (EMA), Medicines and Healthcare products Regulatory Agency (MHRA), and Product Development and Management Association (PDMA). Early engagement allows teams to understand expectations, to implement changes if needed, and to develop appropriate risk mitigation strategies to facilitate the approval process.

it is imperative that quality and regulatory teams maintain positive working relationships and regular communication with all relevant regulatory agencies”

Though the industry is harmonised in many areas, when developing a drug for international approval, it is also important to keep in mind that different regulatory agencies have different standards and expectations when it comes to composition and production. Some health authorities may be more stringent about the use of certain materials than others. They may also have varying standards regarding the appropriate quantity of these materials or residuals. Teams must also accept the variety of analytical procedures these regulatory agencies prefer.

To move past these challenges, it is imperative that quality and regulatory teams maintain positive working relationships and regular communication with all relevant regulatory agencies. This facilitates a chance to gain guidance and address potential deviations, which can prevent delays to clinical programmes.

The drug product development process is often seen as a race to approval and commercialisation, the proverbial “finish line”. By collaborating with global regulatory authorities and mitigating risk, we will maintain sight of our true goal, delivering safe and effective novel therapies to patients.

About the Author

Related topics

Big Pharma, Clinical Development, Drug Development, Drug Manufacturing, Manufacturing, QA/QC, Regulation & Legislation, Research & Development (R&D), Therapeutics

Related organisations

European Medicines Agency (EMA), Medicines and Healthcare Products Regulatory Agency (MHRA), Product Development and Management Association (PDMA), The International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH), US Food and Drug Administration (FDA), Zymeworks

Quality Assurance is the backbone of pharmaceutical innovation. The article underscores its vital role in delivering safe and effective medications to patients. It’s reassuring to see the industry’s commitment to maintaining high standards and ensuring the well-being of those who depend on these life-saving treatments.