The uses and prospects for 3D printing in pharmacology

Posted: 11 June 2020 | Alina Dvoretskaya (3D GENERATION) | 2 comments

Alina Dvoretskaya describes how 3D technologies are used in pharmacology and the benefits these offer to the healthcare industry.

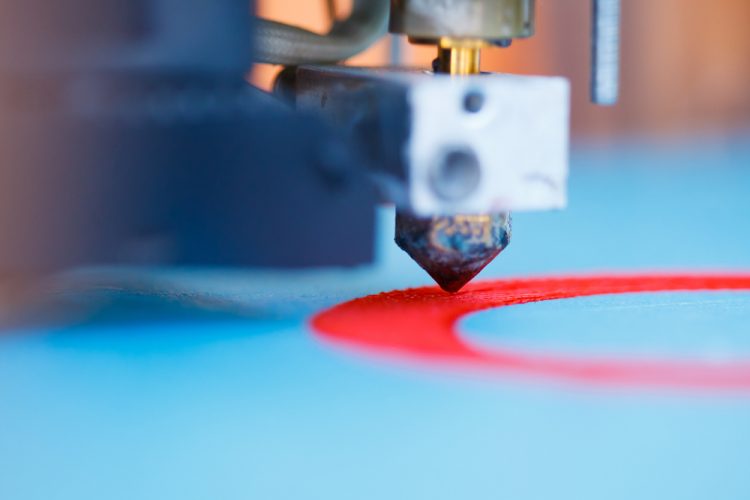

Three-dimensional (3D) technology is considered one of the promising areas of medicine. The world has already seen printed anatomical prostheses, hearing aids, heart valves, biological tissues and many others. Therefore, innovative 3D scanning and printing systems have the potential to open up new opportunities that are difficult to overestimate.

Thanks to the individualisation of the treatment process, 3D technology will lay the foundation for the treatment of less common diseases”

As such, 3D printing also has a great significance in pharmacology. Its use in this area forms the basis of a new concept for patient-centric treatment. Through additive pill manufacturing, personalised medicines and therapies can be developed. This can help patients receive the most effective treatment at the most cost-effective price.

Over the past five years, scientists have been actively exploring the potential of 3D printing in the pharmacology industry. Due to the high flexibility of its nature and almost unlimited possibilities, it has the potential to be revolutionary to medicine.

Benefits of 3D technology

The benefits of 3D technology in compounding pharmacies include:

- the ability to create tablets of any shape and size

- the ability to set the dosage individually for each patient

- the ability to regulate the number of active substances in the composition of the tablet, remove or replace individual components. This will help many people take medicine even if there are contraindications to a single substance.

- the ability to replace a large number of drugs with one tablet, which also reduces the frequency of medication

- the ability to control the process of release of active substances allows to slow down or accelerate the effect of the drug, which will increase the effectiveness of tablets

- the larger availability of drugs that can be obtained at any pharmacy with a 3D printer if a patient has a doctor’s prescription

- eco-friendly production – in the process of manufacturing tablets with a 3D printer, no waste pollutes the environment

- the ability to print small batches of drugs, saving money on the production and testing of drugs in comparison with the traditional method

- the manufacture of tablets on a 3D printer eliminates the possibility to mix up drugs or take other patient’s tablets by mistake

- for the manufacture of drugs, a 3D printer is the only piece of required equipment. Therefore, mini-factories for the production of tablets can be in each local region. Such printers can even be installed in military hospitals and taken on space expeditions. This could help patients to get appropriate medications even during a pandemic, natural disaster or other events.

One of the new features of 3D printing in the future will be the delivery of custom-made drugs to remote places in the world where pharmaceutical supply chains are poorly developed. In 2020, many companies are already operating in the telemedicine field.

The prospects for 3D printing in compounding pharmacy are far-reaching. By installing 3D printers in the pharmacies of each locale, it will be possible to raise the level of medicine accessibility to a new level.

Currently, medicine is computerised, patients have medical history cards and detailed information about treatment in an online format. Therefore, if all pharmacies are provided with printers, a patient could move or travel and not have to worry that they will be unable to get his treatment or that they will not be able to find the right pills elsewhere in the world.

What is important to remember about 3D printing of pharmaceuticals

A large number of studies have revealed that there are some limitations during the 3D manufacturing of tablets. These are related to the fact that for each individual medicine, specific substances and ingredients are required.

To create tablets, four kinds of 3D printing can be used:

- Fused Deposition Modelling (FDM)

- Selective Laser Sintering (SLS)

- Stereolithography (SLA)

- 3D technology for creating biological tissues (3D bioprinting).

Thus, it is possible to choose the method of printing only after a detailed study of a specific disease, its treatment mechanisms and the identification of the required active substances to combat the disease. Before creating a prescription for the manufacture of tablets, it is important to consider the compatibility of materials and type of printing.

In summary, 3D printing has already shown an attractive flexibility for the manufacture of drugs. The development of this branch in pharmacology will help to cure many rare and common diseases. 3D technologies will reduce the period of treatment, remove negative symptoms and eliminate contraindications to tablets due to an individualised approach. The compactness of 3D platforms, computerisation of displays which will allow receipt of real-time prescription from doctors for the production of 3D tablets, will also help to provide even remote areas with essential medicine.

About the author

Alina Dvoretskaya works at 3D GENERATION, which specialises in 3D printing and creating 3D scanning systems. The author’s interests include the development of modern technologies, VR, AR and artificial intelligence.

Your article is such an informative article. It is glad to read such those articles. Thanks for sharing.

Is it commercially viable to set up a 3D printing pharmaceutical plant. What will be approximate cost of setting up such a plant.