At Interphex 2019, Telstar promotes breakthrough developments in freeze-drying technology

Posted: 29 March 2019 | Telstar | No comments yet

Lyogistics Zero, the only freeze dryer vial automatic loading/unloading system with the ability to have CIP/SIP inside the chamber, and Lyonuc, the new vacuum nucleation induction method suitable for any type of freeze-dryer, are leading cutting-edge solutions for pharma processes…

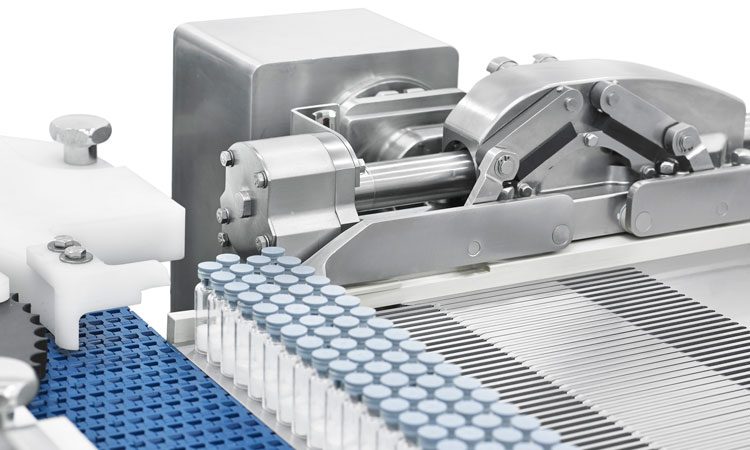

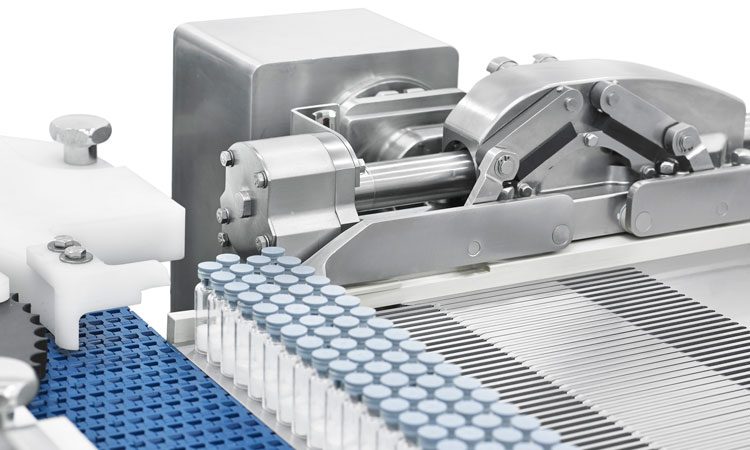

At Interphex (New York April 2-4, 2019), Telstar will be exhibiting the latest solutions in isolation technology systems, sterilisation and pharmaceutical freeze-drying applications, designed to ensure an aseptic and efficient production of pharmaceutical processes. The company will promote the only automatic vial loading & unloading system for freeze-drying processes, which can be cleaned (CIP) and sterilised (SIP) in place, inside the freeze-dryer chamber. Lyogistics Zero is a new generation automatic vial loading & unloading system for GMP pharmaceutical freeze dryers integrating a steam-sterilisable slider with no concealed parts, which is moved by a contact-free magnetic drive mechanism. This innovative system enables the transfer device, or ‘slider’, to remain inside the chamber to undergo cleaning and sterilisation in place along with the internals of the freeze dryer. Suitable for use in production processes involving hazardous products, Lyogistics Zero has been designed to be integrated within aseptic isolators requiring high level protection for the operator (OEL5), the product (ISO5) and the environment.

In the framework of the freeze-drying process, the new Lyonuc®, the nucleation induction method developed by Telstar, will also be presented and demonstrated at Interphex. Suitable for any type of freeze dryer without modifying its main elements or adding gases or external substances, this

The company will be showing the latest generation of sterility test isolators integrated with Telstar’s innovative ionHP bio-decontamination system proven to dramatically decrease cycle times, increase time available for process and reduce running costs. This range of isolators is designed to avoid the risk of false results and to protect the product from both the process and externally generated factors that would compromise its quality.

In addition, a new multi-purpose modular autoclave range designed to minimise footprint while maximising maintenance access will also be promoted in the field of pharmaceutical sterilisation. Telstar Sterimega Plus is a new compact steam sterilising autoclave with GMP design, including hinged front-facing access panels which open completely to provide full access to the technical area of the equipment. This configuration has been specifically designed for use in the pharmaceutical industry and laboratories with limited space. The Sterimega range is primarily for steam sterilisation of solid products and porous and gravitational liquid loads in the pharmaceutical industry and can be configured in pass through configuration for sterilisation and/or bio-decontamination processes.

Finally, the company will promote the new standardised range of downflow booths for weighing and sampling, used for materials-dispensing and dosage processes. Designed and made in the US, the new standardised modular and compact range of cabinets allows expediting the design and installation process of cabinets, significantly reducing delivery times, making easier the full integration of the equipment to the facility architecture or a standalone installation as required when installing within existing locations.

Telstar, part of the azbil Group, is an expert in the development of highly complex projects, from integrated process equipment to design, engineering and construction of complete turnkey pharmaceutical and biotech production facilities, critical installations, clean rooms, and R&D laboratories. Acknowledged as one of the 10 major suppliers for the pharmaceutical industry, Telstar is one of the few international manufacturers able to offer integrated process solutions for the biopharmaceutical industry with in-house sterilisation, freeze-drying, containment, process water & waste treatment, clean air and cold storage technologies. Telstar invests 3 percent of its turnover in research, development and innovation of its technologies and equipment.