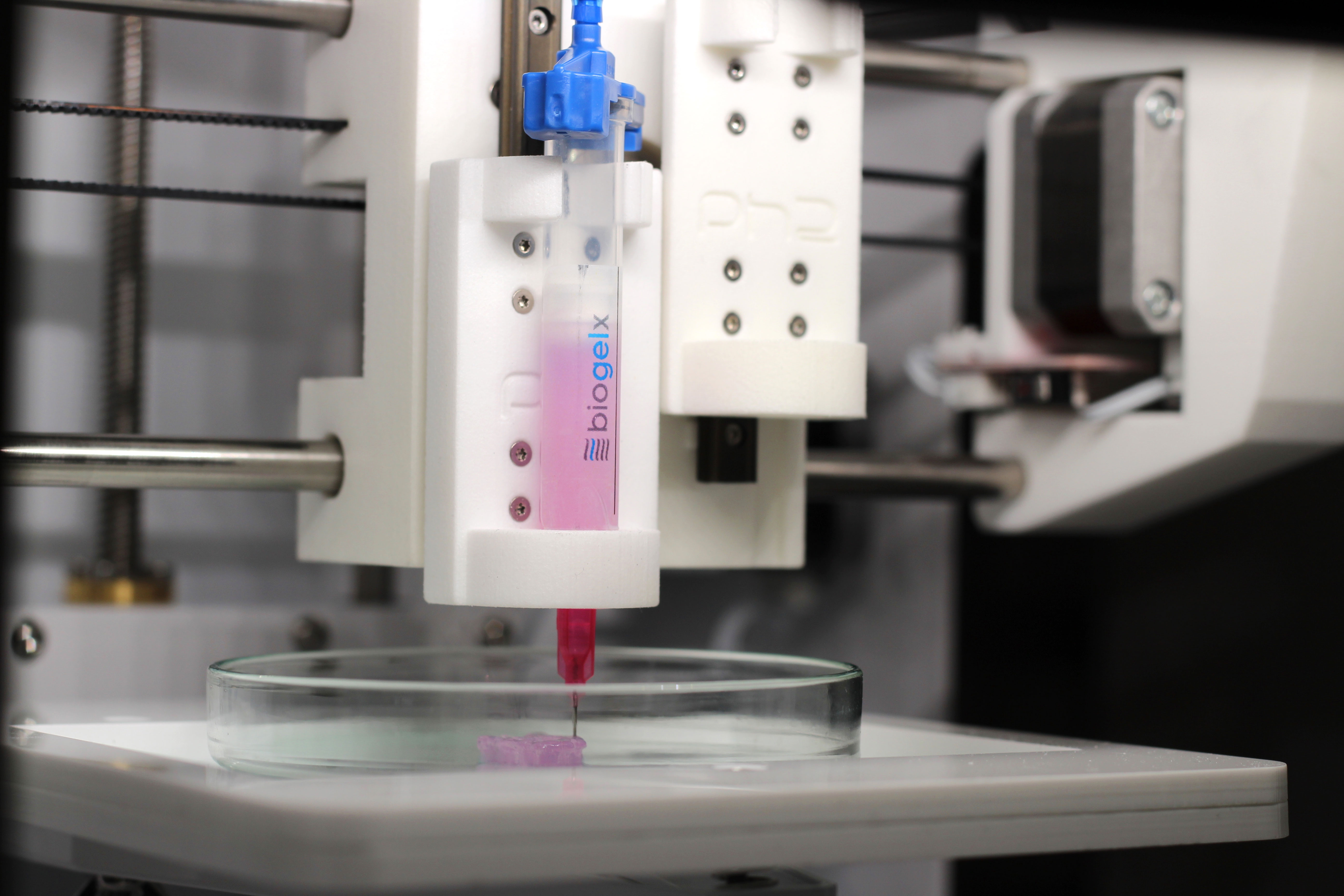

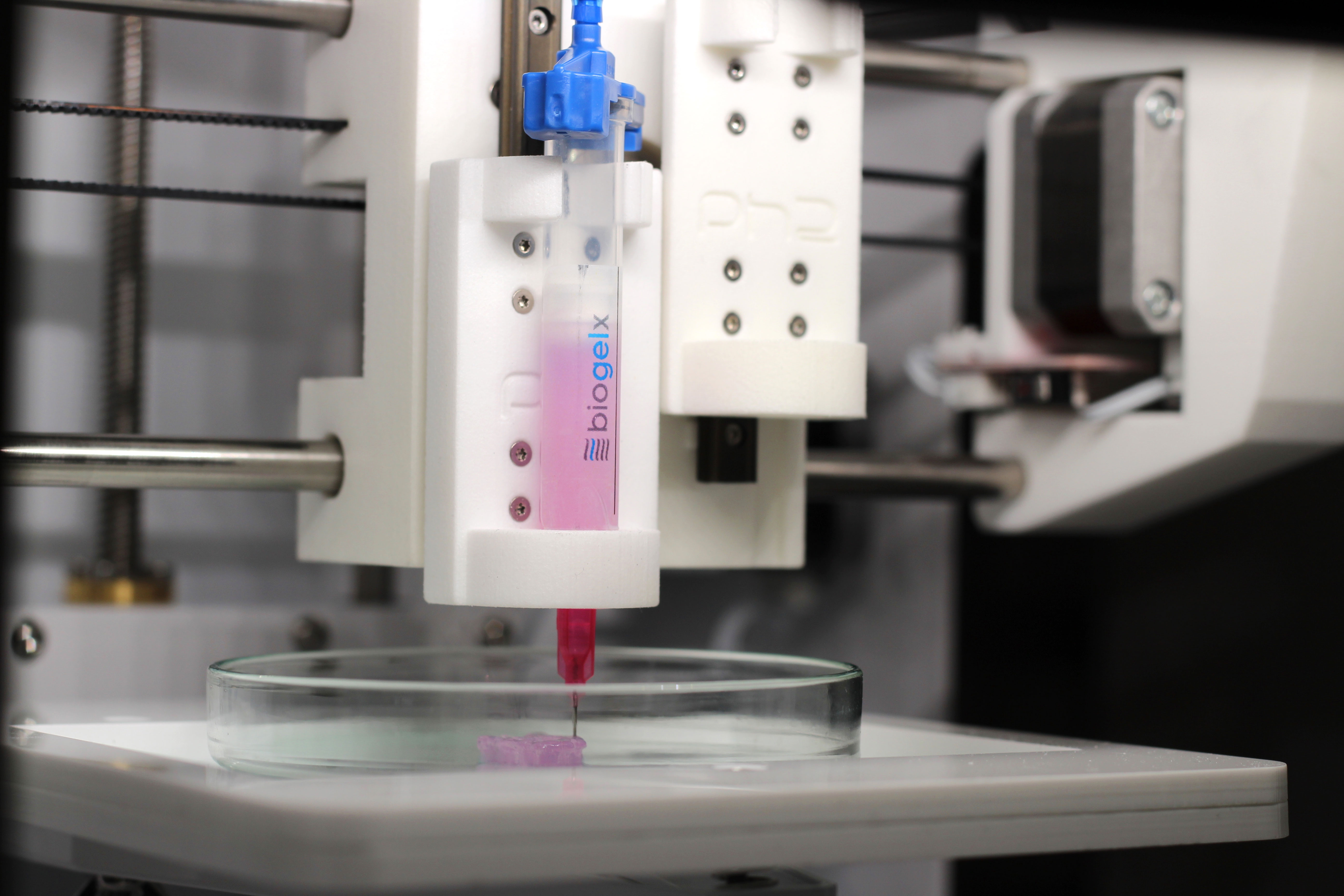

Developing a 3D bioink for use in regenerative medicine

Posted: 27 March 2018 | Michael Connolly - Product Development Manager - Biogelx Ltd. | No comments yet

The concept of developing a bioink that can be used for all cell types and all printing techniques is at best unrealistic and at worst impossible. What is much more achievable and also more desirable is a modifiable, modular system…

The concept of developing a bioink that can be used for all cell types and all printing techniques is at best unrealistic and at worst impossible. What is much more achievable and also more desirable is a modifiable, modular system. A base material in which mechanical properties can be easily adapted for the chosen additive method and then formulated for each specific cell type or multiple cell types involved in the end application.

3-dimensional (3D) bioprinting utilises 3D printing technology to produce functional miniaturised tissue constructs from biocompatible materials, cells and supporting components such as cell culture media, and involves the layer-by-layer, accurate deposition of these materials into precise geometries with the goal being the creation of anatomically correct biological structures.

The term ‘bioink’, encompasses materials that mimic an extracellular matrix to support the adhesion, proliferation, and differentiation of living cells in a 3D environment. Bioinks distinguish themselves from traditional biomaterials such as hydrogels, polymer networks, and foam scaffolds due to their ability to be deposited by a 3D printer into a pre-defined structure. There is increasing demand for alternative fabrication approaches to develop tissues and organs as conventional techniques are not capable of fabricating constructs with required structural, mechanical, and biological complexity. 3D bioprinting offers great potential to fabricate highly complex constructs with precise control of structure, mechanics, and biological matter. This is especially relevant in the field of implantable regenerative medicine clinical products.

As is often the case to enable a leap in scientific understanding and the next frontier in product development, collaboration between multi-disciplined partners is key. With an ultimate aim to accelerate the realisation of biomanufacturing of human tissue products to a much shorter timescale than forecasted, and thus increase the availability of replacement tissues and organs to patients, the development of platform technologies able to assist in bringing regenerative medicine products to market is critical.

To do this we at Biogelx are working together with a consortium of world-leading academic institutions and industry experts in the fields of regenerative medicine, bioprinters, biomaterials, and media manufacture. The need for such an advanced biomanufacturing initiative is an indication of the rapid adoption of 3D bioprinting technology, which can be partly attributed to significant advancement in additive manufacturing technologies over the last 5 years, now translating to life science markets. Release of affordable 3D bioprinters from manufacturers has increased significantly; however, a major roadblock identified is the development of technologies that facilitate the implementation of these bioprinters in regenerative medicine clinical manufacturing. One of the most vital, but to date limiting, components required for widespread adoption of bioprinting in regenerative medicine is the availability of effective bioinks. Such a material must offer properties suited to both the printing process and to hosting/ maintaining the viability of the cells within the scaffold structure.

The rest of this content is restricted - login or subscribe free to access

Why subscribe? Join our growing community of thousands of industry professionals and gain access to:

- bi-monthly issues in print and/or digital format

- case studies, whitepapers, webinars and industry-leading content

- breaking news and features

- our extensive online archive of thousands of articles and years of past issues

- ...And it's all free!

Click here to Subscribe today Login here

Related topics

3D printing, Microbial Biological Manufacturing, Microbiology, Regenerative Medicine