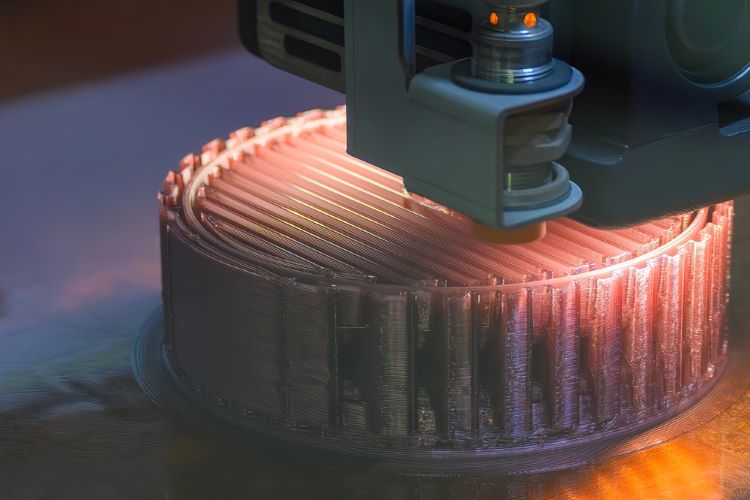

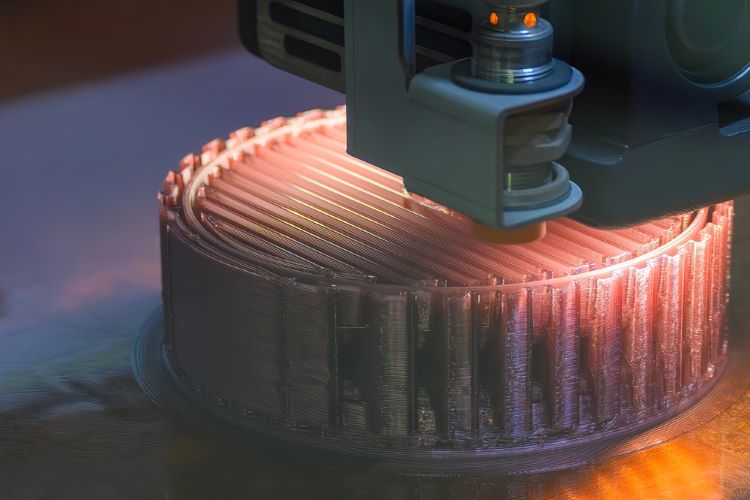

Could novel 3D printing method enhance intestinal drug delivery?

Posted: 26 February 2025 | Catherine Eckford (European Pharmaceutical Review) | No comments yet

The research suggests that the innovative 3D printing method has “great” potential for personalised treatments of intestinal inflammatory diseases.

A study has demonstrated a new approach to prepare tablets for intestinal drug delivery by combining two 3D printing techniques. Using both selective laser sintering (SLS) and fused deposition modelling (FDM), the technique has potential to achieve delayed and prolonged drug release, according to the findings.

Key findings from the 3D printing drug delivery study

“[a] laser speed of 90 mm s−1 was suitable for producing [3D printed tablet] cores with relatively short disintegration time and sufficient tensile strength”.

Tranová et al. explained that a “laser speed of 90 mm s−1 was suitable for producing cores with relatively short disintegration time and sufficient tensile strength. This formulation, enriched by paracetamol, was subsequently FDM-coated”.

The team conducted in vitro dissolution testing on these FDM-coated cores. The tablet coating was robust as it exhibited acid-resistant properties, “with no drug release in the pH of 1.2 during the first 120 min of dissolution testing”, the data showed.

Therefore, the FDM coating has potential for tailoring dissolution profiles for intestinal drug delivery, the authors concluded.

Tranová et al. also shared that the coating shells, “made from 95 percent HPMC and five percent pectin accounted for 68.7 percent of the total tablet weight”, enabled modified drug release and greater mechanical resistance of the 3D printed tablet.

Additionally, the combined 3D printing method gave the shells a smooth surface that were “without major defects”.

The authors remarked that one of the main benefits of the proposed new intestinal drug delivery system is that it offers a personalised approach that can be tailored to the needs of patients.

Findings from this study were published in Macromolecular Materials and Engineering.

In similar research reported on EPR in 2024, different investigators developed a 3D personalised drug delivery system using thermal melt extrusion together with fused deposition modelling 3D printing. While this particular study focused on optimising tablet structure, Tranová et al. experimented with tablet coating variations to enhance controlled drug release profile.

Related topics

Biopharmaceuticals, Data Analysis, Dissolution Testing, Drug Delivery Systems, Drug Development, Drug Manufacturing, Formulation, Manufacturing, Personalised medicine, Research & Development (R&D), Technology, Therapeutics