Sustainable PFAS-free synthesis for pharmaceutical compounds

Posted: 30 August 2024 | Catherine Eckford (European Pharmaceutical Review) | No comments yet

The novel, environmentally-friendly synthesis strategy holds potential for manufacturing scale up, according to the research.

Researchers have developed an innovative synthesis method for pharmaceutical compounds that does not require the use of PFAS reagents. Caesium fluoride salt was used as alternative fluorine source.

The approach resulted in a combination of various anions with a range of substrates which produced multiple fluorinated products with relevance to pharmaceutical syntheses, according to the team. One of the main benefits of the proposed procedure is that it “offers greater versatility and flexibility over more common procedures using traditional chemical glassware”.

They reported “very satisfactory yields”. Moreover, the researchers stated that based on their data, operational parameters such as reaction times showed promise for future academic and industrial applications.

Spennacchio et al. highlighted that synthesis of many pharmaceutical compounds “often requires bespoke fluorinated reagents”. Thus, their research is important because PFAS compounds are set to face future legislation.

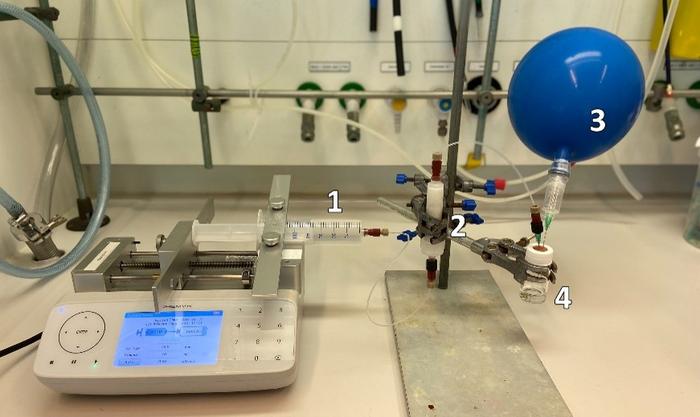

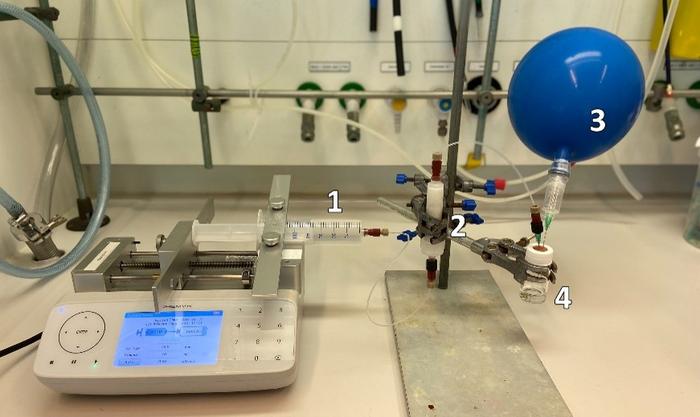

Laboratory set-up of the microfluidic flow module for generating reactive N–, S– and O–CF3 anions. 1: Solution containing precursor molecules. 2: Packed bed reactor containing the caesium fluoride salt. 3: Nitrogen filled balloon that prevents pressure build-up. 4: Reception vial equipped with stirring bar.

(Credit: Universiteit van Amsterdam and Van ‘t Hoff Institute for Molecular Sciences)

Achieving PFAS-free synthesis

[the proposed PFAS-free synthesis method] offers greater versatility and flexibility over more common procedures using traditional chemical glassware”

Notably, the new PFAS-free synthesis protocol using microfluidic flow module “enables coupling of the CF3 group through a sulphur (S), nitrogen (N) or oxygen (O) atom.”

The team remarked that the “high surface area of the salt in the packed bed [flow reactor] as well and the improved mixing of the organic intermediates” enabled fluorination with “high efficiency”.

Importantly, the sustainable streamlined platform also provides enhanced safety as all formed intermediates were contained within the microfluidic system, Spennacchio et al. explained.

This novel system was developed by chemists at the University of Amsterdam and in partnership with members of industry, including AstraZeneca.

The paper reporting the outcomes from the alternative PFAS study was published in Science.

Related topics

Data Analysis, Downstream, Drug Manufacturing, Industry Insight, Microfluidics, Research & Development (R&D), Sustainability, Technology, Therapeutics

Related organisations

University of Amsterdam, Van ‘t Hoff Institute for Molecular Sciences