Antibiotic manufactured via continuous-flow for first time

Posted: 7 August 2023 | Catherine Eckford (European Pharmaceutical Review) | No comments yet

Continuous-flow manufacturing of the antibiotic cefazolin can cover mass production within compact manufacturing facilities and contribute to a stable drug supply, researchers have reported.

For the first-time, researchers have successfully and safely produced the antibiotic cefazolin using continuous-flow manufacturing. While usually produced via batch manufacturing, this latter process is time-consuming, requires specialised equipment results in a large amount of waste.

On the other hand: “The method we have developed can cover mass production within compact manufacturing facilities, does not incur huge equipment costs, and can provide a pharmaceutical-grade drug safely and securely,” explained Professor Shu Kobayashi from the Department of Chemistry at the Graduate School of Science.

“Demand for this antibiotic fluctuates wildly and it is a drug that is better to not prepare too far in advance due to its instability,” stated Project Professor Haruro Ishitani, also from the Department of Chemistry. “So a big benefit of continuous-flow manufacturing is that it is easy to adjust the production volume as needed.”

Continuous-flow manufacturing could help smaller communities and hospitals manufacture essential drugs such as antibiotics, as needed, the paper noted.

EPR Podcast Episode 18 – Embracing continuous manufacturing – Trish Hurter, Lyndra Therapeutics

Producing cefazolin via continuous-flow manufacturing

The method

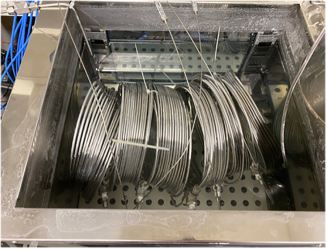

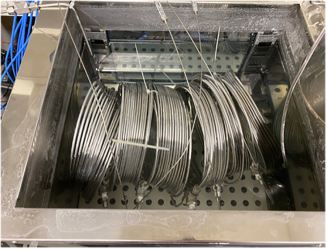

The team used two connected reactors to produce cefazolin from readily available commercial raw materials. Firstly, the raw materials and reagents were pumped into the first reactor. Then these substances were moved into another reactor where an additional raw material was incorporated. From there flowed the cefazolin.

Credit: 2023 H. ISHITANI

Optimising the environment inside the reactors, ie, the temperature, transfer speed and mixing ratio of reagents was a challenge, however. The team reported that having control of these elements ensured that the final product was of high-purity. According to the researchers, the continuous-flow manufacturing method was substantially superior to conventional batch manufacturing; it could be further optimised too, they added.

Many compounds can be synthesised by continuous-flow manufacturing, commented Ishitani. “By adopting this method, we believe that we can contribute to a stable drug supply, respond to rare diseases and disasters, and aid new drug development.”

This study is published in the Bulletin of the Chemical Society of Japan.

Related topics

Active Pharmaceutical Ingredient (API), Antibiotics, Continuous Manufacturing, Drug Development, Drug Safety, Drug Supply Chain, Industry Insight, Manufacturing, Research & Development (R&D), Technology, Therapeutics