Research team discover new reaction for making tertiary amines

Posted: 27 April 2022 | European Pharmaceutical Review | No comments yet

The new chemical reaction, a carbon-hydrogen amination cross-coupling reaction, creates a faster, simpler way of making tertiary amines without the inherent limitations of classic methods.

A University of Illinois at Urbana-Champaign research team has discovered a way to produce a special class of molecule that could open the door for new drugs to treat currently untreatable diseases.

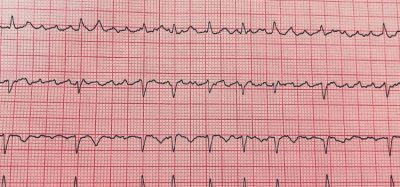

The research team have discovered a new carbon-hydrogen amination cross-coupling reaction, that creates a faster, simpler way of making tertiary amines without the inherent limitations of classic methods. The researchers believe this could also be used to discover new reactions with nitrogen.

More than 40 percent of drugs and drug candidates contain amines, and 60 percent of those amines are tertiary, so named for the three carbons that are bonded to a nitrogen.

This new reaction transforms the traditional tertiary amine building process – with its classic chemical reactions that require highly-specialised conditions specific to each molecule – into a procedure that can be carried out in general conditions open to air and moisture with the potential for automation.

This new procedure uses a metal catalyst discovered by the research group (Ma-WhiteSOX/palladium) and two building blocks— abundant hydrocarbons (olefins containing adjacent C—H bond) and secondary amines— to generate a variety of tertiary amines.

This has the potential for chemists to take a lot of different secondary amines and couple them to a lot of different olefins, both of which can either be bought or easily made.

“These are stable starting materials,” explained Lycan Professor of Chemistry and research team leader, M. Christina White. “You could have them in individual containers, mix and match them, and using our catalyst make many different combinations of tertiary amines. The flexibility of this reaction makes the discovery process for tertiary amine drugs easier.”

This highly flexible system for making tertiary amines is also very practical.

“You could, in principle, run it on your stove top,” White continued. “You don’t need to handle it with a lot of precautions, you can run it open to air and you don’t have to exclude water. You just need your starting materials, the palladium/SOX catalyst and a little heat. It should work just the way we are doing it in the lab.

“Because the conditions are so simple and work for so many different amines and olefins there is great potential to adopt this reaction for automation,” she continued.

The major challenge the team overcame in this discovery was solving a long-standing problem in C—H functionalisation chemistry: replacing a hydrogen atom on a molecule’s carbon framework with a basic, secondary amine to directly make tertiary amines.

Metal catalysts prefer interacting with basic amines rather than the C—H bonds in the olefin. The team hypothesised that amine salts (amine-BF3 salts that are easy to use and store) can prevent this interaction with the catalyst.

Like a dam modulating the flow of water, the team’s palladium/SOX catalyst regulates the slow release of amines from the salts as well as mediates coupling the secondary amine and hydrocarbon to form the tertiary amine product.

Showcasing the power of this new chemical reaction, the researchers made 81 tertiary amines in their study, coupling a wide range of complex, medicinally relevant secondary amines to many complex olefins containing reactive functionality. This includes functionality that is reactive with secondary amines in the traditional tertiary amine manufacturing processes.

Related topics

Drug Development, Drug Manufacturing, Research & Development (R&D), Technology, Therapeutics