Miniaturisation helps overcome limitations of PAT, say experts

Posted: 3 November 2021 | Hannah Balfour (European Pharmaceutical Review) | No comments yet

Researchers review how miniaturised process analytical technologies (PAT), microfluidic affinity assays and microchip capillary electrophoresis, enhance bioprocess monitoring and control.

According to researchers, “more efficient tools to optimise, understand, monitor and control the manufacturing processes of biopharmaceuticals… are desirable”. This is especially true during process development, which is currently undertaken by trial and error. Process analytical technologies (PAT) are one method of improving efficiency, providing real-time measures for process development, monitoring and control. However, Pinto et al. explains that PAT currently has several limitations:

- most medium components are tuned based on a small number of parameters, rather than directly quantified, limiting mechanistic understanding

- live cells used in manufacturing are inherently variable

- more by-products than currently analysed can affect cell cultures

- miniaturised bioreactors (two to 15ml volume) have limited analytical options and only produce small sample volumes (0.2–1.5 ml)

- lack of information about culture components limits the power of mathematical process modelling

- technologies able to detect a wider range of culture components are slow and laborious.

In their review published in Current Opinion in Biotechnology, Pinto et al. stated that miniaturisation of PAT for mammalian cell cultures could enable a deeper knowledge and control of a larger panel of culture components which would be highly beneficial for process optimisation, control and robustness.

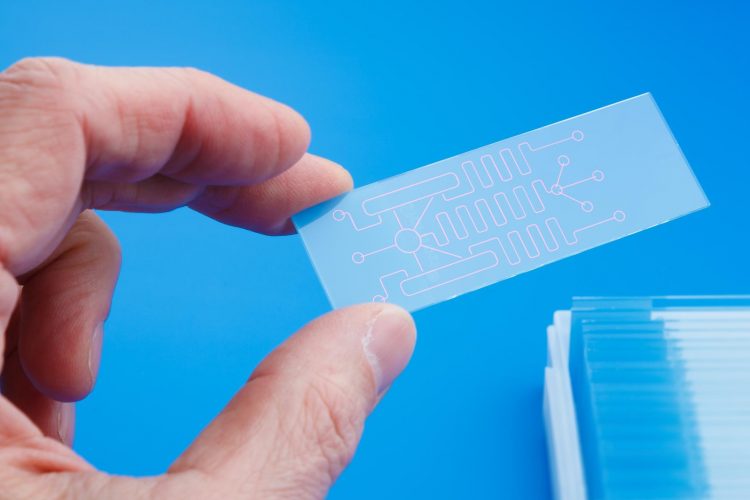

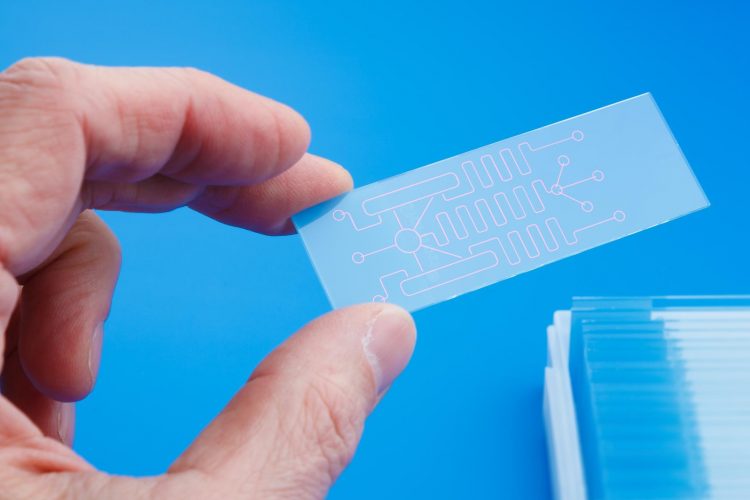

According to the authors, recent advances in microfluidic affinity assays and microchip capillary electrophoresis (MCE) enable the at-line detection of a variety of metabolites, proteins and critical quality attributes (CQAs) in a bioprocess. Moreover, miniaturisation of microfluidics and CE enables PAT at reduced cost and without need of complex instruments such as mass or other spectroscopies.

The review details how microfluidic immunoassays leveraging specific probes can be used for at-line protein measurements, including product titer and host cell proteins (HCP). For instance, the use of aptamers rather than monoclonal antibodies as probes enables label-free monitoring of proteins with a limit of detection of approximately one μg/ml without need of sample pre-treatment. Additionally, cartridge-based immunoassays coupled with fluorescent detection enable HCP detection with a four-fold smaller sample volume and assay duration, while also having a higher level of reproducibility.

With CE, they wrote, miniaturised MCE platforms offer high separation efficiency, short analysis time and negligible waste generation, as well as being high throughput. MCE requires 10x less chemicals per analysis compared to CE, and is estimated to cost up to 20-fold less than high performance liquid chromatography (HPLC), the most commonly used PAT. Moreover, Pinto et al. emphasised that MCE’s smaller size and increased portability potentially allow for in-line analysis.

The authors concluded that miniaturisation of analytical methods is a potential solution for the limitations of PAT and that with automation, microfluidics and MCE enable PAT at reduced cost and complexity.